Gas Sensors Powered by VCSELs: Precision Detection from a VCSEL Manufacturer’s View

Gas Sensors sit quietly behind many safety-critical and environmental systems. They watch over factory floors, check emission stacks, monitor indoor air and even protect families from invisible household leaks. As performance expectations rise, traditional sensing methods are reaching their limits—especially on size, power and selectivity.

This is where VCSELs (Vertical-Cavity Surface-Emitting Lasers) make a real difference. As a dedicated VCSEL manufacturer, Ace Photonics integrates laser technology designed for 750–1550 nm operation into demanding sensing platforms, including Gas Sensors for CO₂, oxygen and other key molecules.

1. What Makes VCSELs So Attractive for Gas Sensors?

1.1 VCSEL basics in the context of gas detection

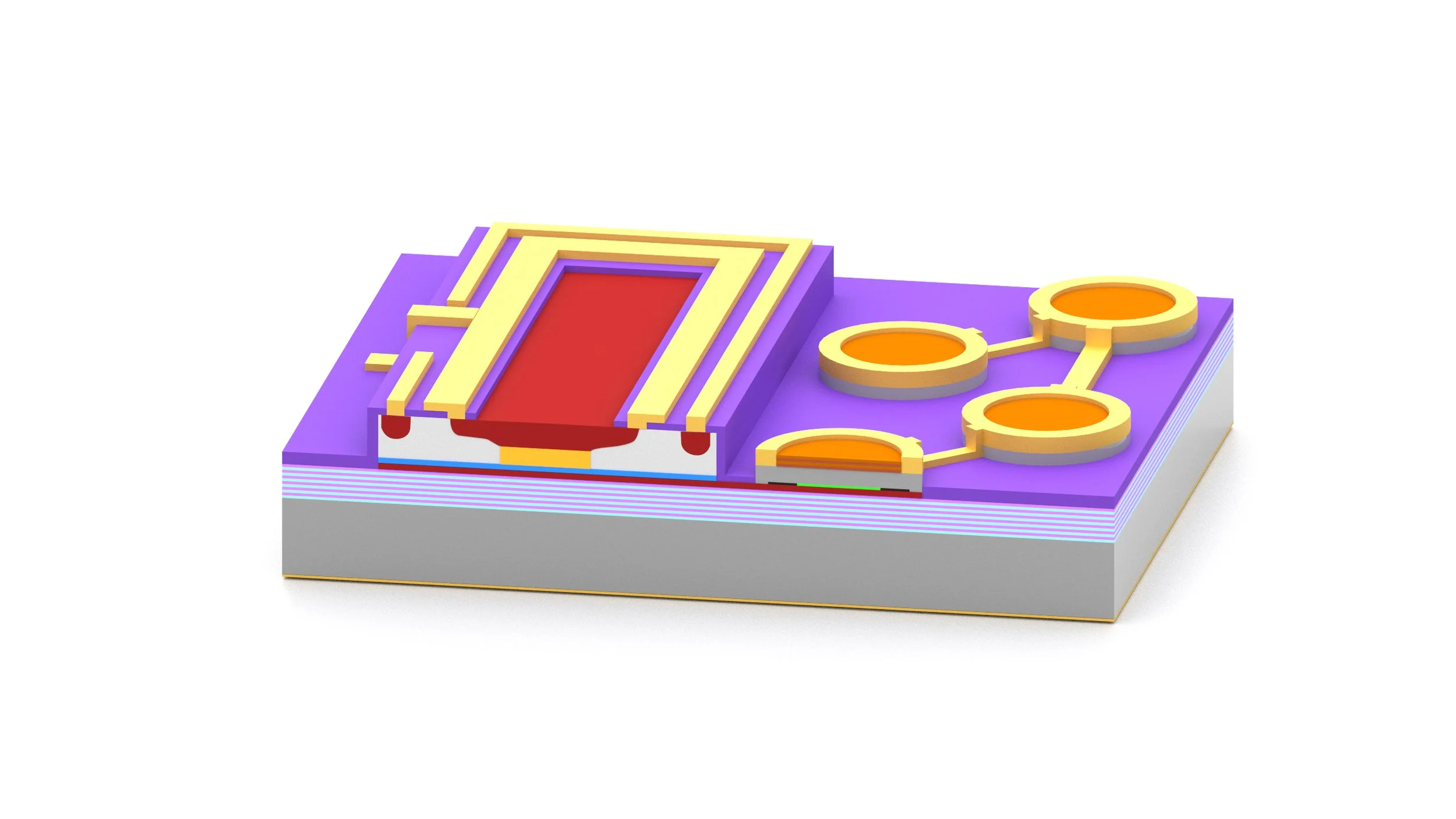

A VCSEL is a semiconductor laser that emits light vertically from the surface of the chip, instead of from the edge like a conventional EEL (edge-emitting laser). This vertical cavity architecture offers several advantages for Gas Sensors:

Compact footprint – ideal for tightly integrated sensor heads.

Low power consumption – supports battery-powered and IoT monitoring nodes.

Wafer-level testability – every die can be characterized before dicing, improving yield and consistency.

Narrow, easily tunable wavelength – crucial for targeting specific gas absorption lines.

For optical Gas Sensors that rely on absorption spectroscopy, these properties translate directly into better stability, higher accuracy and lower total system cost.

1.2 Why VCSELs outperform traditional laser sources in Gas Sensors

Conventional laser diodes or broadband light sources often suffer from:

Higher operating current and heat load.

Larger, more complex optical packaging.

Limited wavelength control and tunability.

VCSELs, by contrast, can be engineered at wavelengths such as 760 nm for oxygen or other absorption bands relevant to greenhouse and exhaust gases, offering:

Fine wavelength control through current and temperature tuning.

Stable, single-mode emission for precise spectroscopic measurements.

Scalable arrays when applications require multi-point sensing.

For Gas Sensors, that means smaller modules, lower energy budgets and better selectivity.

2. How VCSELs Upgrade the Performance of Gas Sensors

2.1 Higher sensitivity and accuracy

Optical Gas Sensors typically measure how much laser light is absorbed at a wavelength where the target gas has a strong absorption line. Because Ace Photonics VCSELs can be closely aligned with these lines and finely tuned, the sensor can:

Detect trace-level concentrations of gases such as CO₂, O₂, CH₄ or VOCs.

Suppress interference from non-target gases by choosing highly selective wavelengths.

Maintain accuracy over temperature thanks to carefully engineered epitaxy and cavity design.

This sensitivity is particularly important in environmental monitoring and medical or life-science applications where ppm or even ppb-level changes matter.

2.2 Cost-effective and scalable sensor architectures

VCSELs are manufactured on wafers and tested at wafer level, which simplifies volume production. For Gas Sensors this provides:

Lower cost per channel compared with many edge-emitting solutions.

Easier integration into compact sensor heads or multi-channel modules.

A straightforward path to scalable production—whether you need a few thousand devices or true high-volume deployment in automotive and consumer products.

Combined with robust packaging—such as the high-temperature, non-magnetic VCSEL packages offered by Ace Photonics—these devices can be deployed even in harsh environments up to 150 °C.

3. Key Application Domains for VCSEL-Enabled Gas Sensors

3.1 Environmental monitoring and emissions control

Regulators and operators increasingly rely on Gas Sensors to track pollutants and greenhouse gases. VCSEL-based systems help by providing:

Accurate CO₂, NOx and SOx measurements over long periods.

Stable calibration and low drift, reducing maintenance overhead.

Compact sensor nodes that can be distributed across industrial sites or smart-city infrastructure.

3.2 Industrial safety and leak detection

Chemical plants, refineries and processing facilities all depend on fast, reliable gas leak detection. VCSEL-powered Gas Sensors can deliver:

Rapid response to small leaks, helping prevent accidents.

Continuous monitoring in confined or high-risk areas, with low power draw.

Integration into existing safety and SCADA systems via digital outputs.

3.3 Automotive exhaust and under-the-hood sensing

In the automotive sector, VCSELs at wavelengths such as 760 nm are particularly attractive for exhaust gas and exhaust gas temperature sensing:

Monitoring combustion gases and temperature to improve engine efficiency.

Supporting advanced after-treatment and emission-control strategies.

Enabling compact sensor modules that survive vibration and elevated temperatures.

3.4 Smart home and IoT Gas Sensors

For residential and IoT devices, Gas Sensors must be small, affordable and power-efficient. VCSELs fit naturally here:

Low-power operation extends battery life in wireless detectors.

Compact modules can be integrated into HVAC controllers, smart alarms and home hubs.

Multi-gas detection is possible when combining VCSELs at different wavelengths or with multi-pass optical cells.

4. Ace Photonics: VCSEL Manufacturer Focused on Gas Sensing Needs

From the perspective of a VCSEL producer, Gas Sensors impose strict requirements on wavelength accuracy, stability and packaging. Ace Photonics is structured to meet those demands end-to-end.

4.1 Customized VCSEL solutions across 750–1550 nm

Ace Photonics specializes in high-performance VCSELs and VECSELs spanning roughly 750–1550 nm, enabling coverage of key absorption bands used in gas detection and related spectroscopy.

For Gas Sensors, this means:

Selecting wavelengths such as 760 nm for oxygen, or others appropriate for CO₂ and hydrocarbons.

Tailoring epitaxial structures and device design for specific absorption lines.

Adjusting output power, beam shape and package style to fit different sensor architectures.

4.2 From wafer to package: reliability built in

The engineering experience at Ace Photonics—rooted in more than 20 years of VCSEL R&D from a CAS-trained team—covers the full vertical process: epitaxy, device fabrication, packaging and test.

For Gas Sensors, this translates into:

High-temperature VCSEL options for under-hood and industrial installations.

Non-magnetic packages suitable for sensitive measurement systems.

Stable performance verified through comprehensive testing, including for special environments such as aerospace.

By tuning wavelength, package and integration approach, Ace Photonics supports both one-off R&D projects and high-volume platforms.

5. Where VCSEL-Based Gas Sensors Are Heading Next

5.1 Continued miniaturization and lower power

As Gas Sensors move into wearable, portable and embedded use cases, VCSEL technology continues to shrink in footprint while improving efficiency. Future devices are expected to:

Operate at even lower currents with robust single-mode output.

Integrate more functions—such as drivers and monitoring photodiodes—directly into compact modules.

Pair with low-cost optics or photonic integrated circuits for fully miniaturized sensing heads.

5.2 Smarter, connected sensing networks

VCSEL-enabled Gas Sensors are also a natural fit for connected systems:

Cloud-linked environmental monitoring and industrial IoT.

AI-assisted analytics that correlate gas concentration patterns with process conditions or safety events.

Distributed sensor networks in smart buildings and smart cities.

By combining stable, wavelength-selective light sources with modern data infrastructure, operators can move from periodic sampling to continuous, predictive monitoring.

6. Summary: Why VCSELs Belong Inside Modern Gas Sensors

Bringing the perspective of a VCSEL manufacturer, the integration of VCSELs into Gas Sensors is more than a trend—it is a structural shift in how gas detection is designed and deployed:

Higher sensitivity and selectivity thanks to narrow, tunable wavelengths aligned with specific gas absorption lines.

Lower power and smaller form factor, enabling portable, automotive and IoT Gas Sensors.

Better scalability and cost efficiency through wafer-level testing and high-yield manufacturing.

Robust packaging and customization, as exemplified by Ace Photonics’ high-temperature, non-magnetic VCSEL solutions tailored to environmental, industrial, automotive and home applications.

As regulations tighten and expectations for air quality and safety grow, VCSEL-based Gas Sensors provide a path to more precise, reliable and widely deployed monitoring. Ace Photonics continues to advance VCSEL technology so that OEMs and system designers can bring the next generation of Gas Sensors to market—smarter, more efficient and ready for the most demanding environments.