VCSEL-Based High Power Laser Diode Array Solutions from Ace Photonics

As a dedicated VCSEL manufacturer, Ace Photonics designs and supplies the core light sources that sit at the heart of every High power laser diode array. From customized VCSEL die to non-magnetic packages and gain chips, our technology is built to deliver stable, high-density optical power for demanding sensing, medical, and industrial systems.

What Is a High Power Laser Diode Array?

A High power laser diode array is a tightly packed assembly of many individual laser emitters arranged on a chip or module to generate a much higher combined optical output than a single diode can provide. By parallelizing dozens or even hundreds of channels, engineers can:

Reach multi-watt to tens-of-watts power levels in a compact footprint

Shape the emission pattern through array geometry and micro-optics

Build redundancy and reliability into critical subsystems

When those emitters are implemented as VCSELs instead of traditional edge-emitting diodes, the array gains notable advantages in efficiency, stability, and system-level integration.

Why VCSELs Are Ideal for High Power Laser Diode Arrays

Surface Emission for Scalable Power

Unlike edge-emitters, VCSELs radiate perpendicular to the wafer surface. This surface emission allows the full array to be probed and tested at the wafer level before dicing or packaging, which:

Reduces cost and yield risk

Simplifies the formation of dense, addressable arrays

Enables flexible 1D/2D array layouts matched to the optical system

High Efficiency and Low Power Consumption

Ace Photonics VCSELs are designed with advanced epitaxial structures, current confinement, and optimized thermal paths. This combination:

Achieves high wall-plug efficiency

Reduces power consumption at a given optical output

Minimizes heat generation inside compact modules

These factors are crucial when multiple VCSEL channels are driven simultaneously in a High power laser diode array.

Stable Wavelength Over Temperature

For many pumping, sensing, and communication applications, wavelength stability directly translates into system performance. Our VCSELs maintain an exceptionally stable wavelength over temperature, and single-mode parts cover approximately the 750–900 nm band while retaining high output and polarization stability.

This stability is especially valuable when arrays are used:

As pump sources for solid-state or fiber lasers

In atomic and quantum sensing where resonant wavelengths (e.g. 795 nm, 895 nm) are critical

In high-precision instruments operating across wide ambient ranges

Compact Size and Flexible Packaging

Because VCSELs are small, planar devices, they fit naturally into compact multi-channel layouts. Ace Photonics offers:

VCSEL die for direct integration into your own arrays

VCSEL packages including non-magnetic housings for quantum and MRI-compatible systems

VCSEL modules with integrated micro-optics for ready-to-use laser subassemblies

This allows array designers to choose the integration level that best matches their own production flow.

Ace Photonics VCSEL Portfolio for High Power Arrays

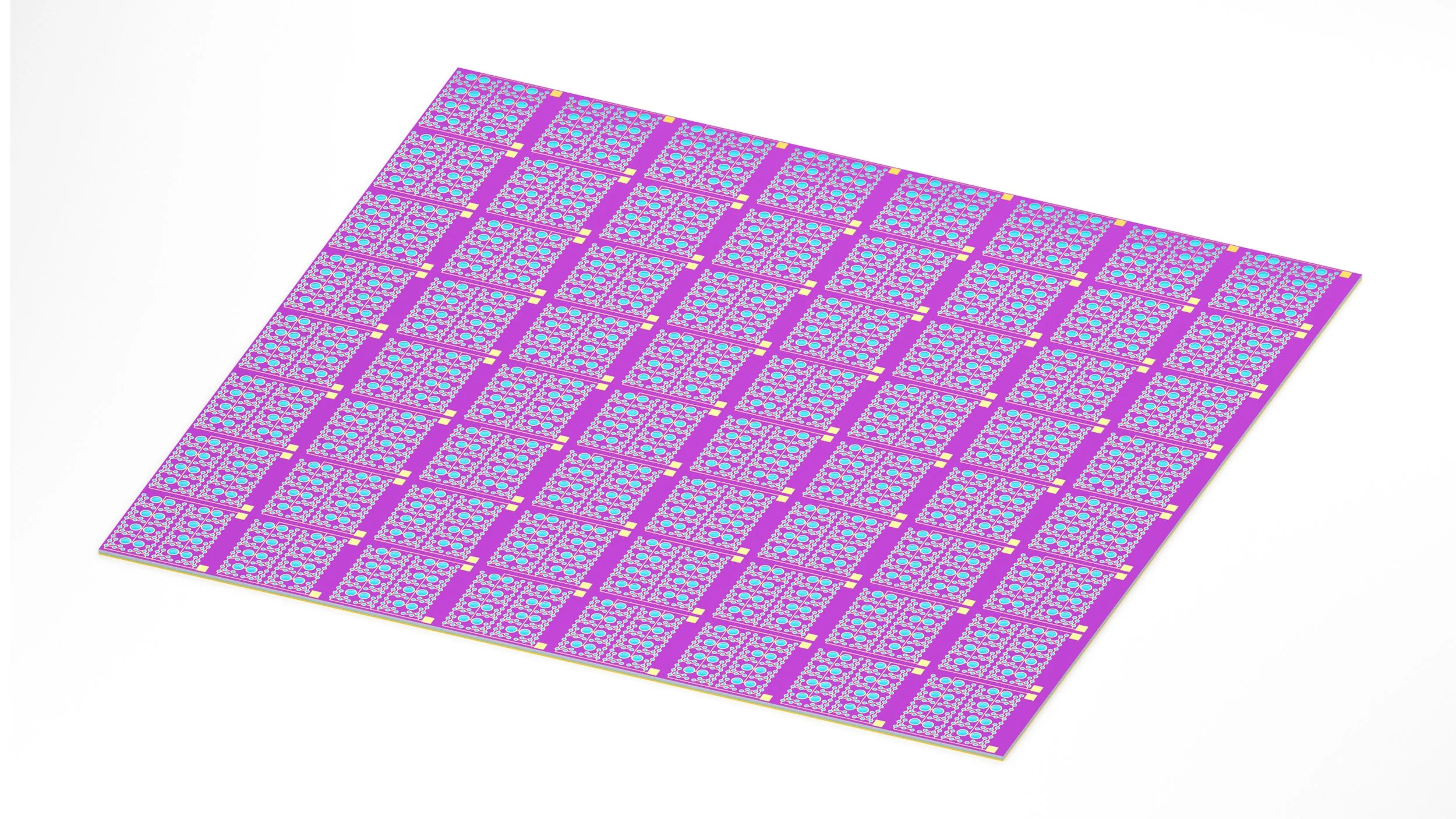

VCSEL Die for Custom Arrays

At the chip level, Ace Photonics offers VCSEL die at key wavelengths such as 760–763 nm, 790–795 nm, and 890–895 nm, with output powers from sub-milliwatt levels up to around 1.8 mW per emitter in catalog products.

Core technologies built into these die include:

Vertical resonant cavity design

Current confinement structures

Optimized thermal paths

Polarization and wavelength control

Array and integration-ready chip layouts

These dies form the foundation for custom High power laser diode array solutions across sensing, LiDAR, facial recognition, optical communication, and medical instrumentation.

VCSEL Modules for High Output and Compact Footprint

Our VCSEL modules combine:

High-output VCSEL arrays

Microlens arrays (MLA) aligned to each emitting channel

Structures optimized for wavelength stability under varying temperature

The result is a compact module with fewer components than a typical edge-emitting laser solution, while delivering high output power and stable wavelength for solid-state laser excitation, laser ignition heads, and 3D sensing illuminators.

VCSEL Gain Chips for High Power Pumping

For applications requiring watt-level power per channel, our VCSEL gain chips can be incorporated into tailored cavity designs. Typical gain chip offerings cover wavelengths such as 1064 nm, 1122 nm, 1154 nm, and 1180 nm with power levels from 1 W up to ≈15 W depending on configuration.

Mounted on copper carriers with customizable packages, these gain chips enable:

High power pump modules for marking and material processing

Frequency-converted visible sources

Multi-watt subassemblies within a High power laser diode array platform

Non-Magnetic VCSEL Packages for Quantum and MRI-Compatible Arrays

Many emerging high power array applications are in environments where even tiny magnetic fields matter. Ace Photonics offers non-magnetic VCSEL packages that:

Replace ferromagnetic can materials with ceramics or specialty composites

Minimize residual fields around atomic magnetometers, gyroscopes, and clocks

Maintain signal integrity in MRI and other strong-field instruments

In a High power laser diode array used for quantum sensing, non-magnetic packaging ensures that increasing channel count does not introduce additional background noise or measurement drift.

Key Applications of VCSEL-Based High Power Laser Diode Arrays

Quantum Sensing and Atomic Devices

Our VCSELs are widely used in:

Chip-scale quantum magnetometers (e.g. SERF atomic magnetometers)

Atomic clocks and quantum gyroscopes

NV-center and alkali-vapor-cell-based sensors

Arrays at resonant wavelengths such as 795 nm and 895 nm provide the optical power density needed for pumping and probing, while narrow linewidth and low noise maintain quantum-grade performance.

3D Sensing, LiDAR, and Facial Recognition

For 3D sensing and structured light systems, VCSEL arrays deliver:

High efficiency (often exceeding 45% at room temperature)

Low divergence beams, tunable with chip-level micro-optics

Options for linear polarization and narrow wavelength spread

These properties make VCSEL-based High power laser diode arrays ideal for facial recognition, gesture sensing, and compact LiDAR modules.

Medical and Biological Instrumentation

VCSEL arrays support:

Optical oxygen sensors with wavelength-tailored emission

Medical monitoring and imaging systems that require low noise and high stability

MRI-compatible illumination using non-magnetic packages

The combination of specific wavelengths, fast modulation, and thermal stability improves measurement speed and accuracy in clinical environments.

Industrial Processing and Laser Pumping

With gain chips in the 1–15 W range and array-ready die, Ace Photonics components are suited to:

Pumping solid-state or fiber lasers for marking, engraving, and micro-machining

Generating high-intensity beams for laser ignition or specialized illumination

Building compact pump submodules inside larger industrial systems

Design and Integration Considerations

Thermal Management in High Power Arrays

As output power scales with channel count, managing junction temperature becomes a primary design task. Our VCSELs and gain chips are supported by:

Thermal management structures at the chip and package level

Package options compatible with heat sinks and active cooling

Operating ambient ratings up to approximately 150 °C for selected VCSEL products

When we work with customers, we jointly optimize array layout, drive conditions, and cooling solutions to maintain efficiency and lifetime.

Alignment and Beam Shaping

Because VCSELs emit perpendicular to the surface with symmetric, low-divergence beams, alignment in multi-channel arrays is more straightforward than with edge-emitters. We support:

MLA (microlens array) integration for precise beam shaping

Tailored array geometries matched to your optics

Wafer-level testing that ensures channel-to-channel uniformity before packaging

Custom High Power Laser Diode Array Development with Ace Photonics

Ace Photonics is not just a catalog supplier; we frequently co-engineer High power laser diode array solutions with system integrators and research teams. Our strengths include:

Custom epitaxial and device design on GaAs-based VCSEL platforms

Expertise in ICP etching, wet oxidation, BCB processing, and other chip-level techniques

Packaging know-how for standard, SMD, and non-magnetic modules

Experience adapting VCSELs for aerospace payloads and harsh environments

Whether you need a custom VCSEL die layout, a non-magnetic array package for quantum sensing, or a high-power gain chip for laser pumping, our team can help translate your system-level requirements into a manufacturable design.

Partner with Us

If you are developing a High power laser diode array for quantum sensing, 3D sensing, medical instrumentation, or industrial laser systems, Ace Photonics provides the VCSEL technology stack—from die and gain chips to modules and packages—to support your roadmap.