High Power VCSEL Array: Powering the Next Wave of Industrial Automation

As a dedicated VCSEL manufacturer, Ace Photonics designs and produces High Power VCSEL Array solutions that bridge advanced photonics with real-world industrial needs. Our GaAs-based VCSEL dies, modules and packages are engineered for demanding environments where precise sensing, fast feedback and long-term stability are critical.

From 3D machine vision on factory lines to quantum-grade sensing, high power VCSEL arrays are becoming a core building block of modern industrial automation systems.

1. Industrial Automation Meets High Power VCSEL Array

Industrial automation has moved from simple, fixed tooling to flexible, software-defined production cells driven by data, optics and AI. Robots, collaborative systems and automated inspection now rely on accurate depth information, stable illumination and compact optical sources that can be embedded directly into machines.

High Power VCSEL Arrays are particularly well suited to this new environment because they combine:

High optical efficiency for low power consumption

Stable output over a wide temperature range

Scalable array architectures supporting multiple emitters

Compact, easily integrated modules and SMD packages

By pairing these arrays with optics such as microlens arrays (MLA), manufacturers can build compact, robust light engines that fit directly into industrial sensors, scanners and robots.

2. What Is a High Power VCSEL Array?

2.1 VCSEL Basics

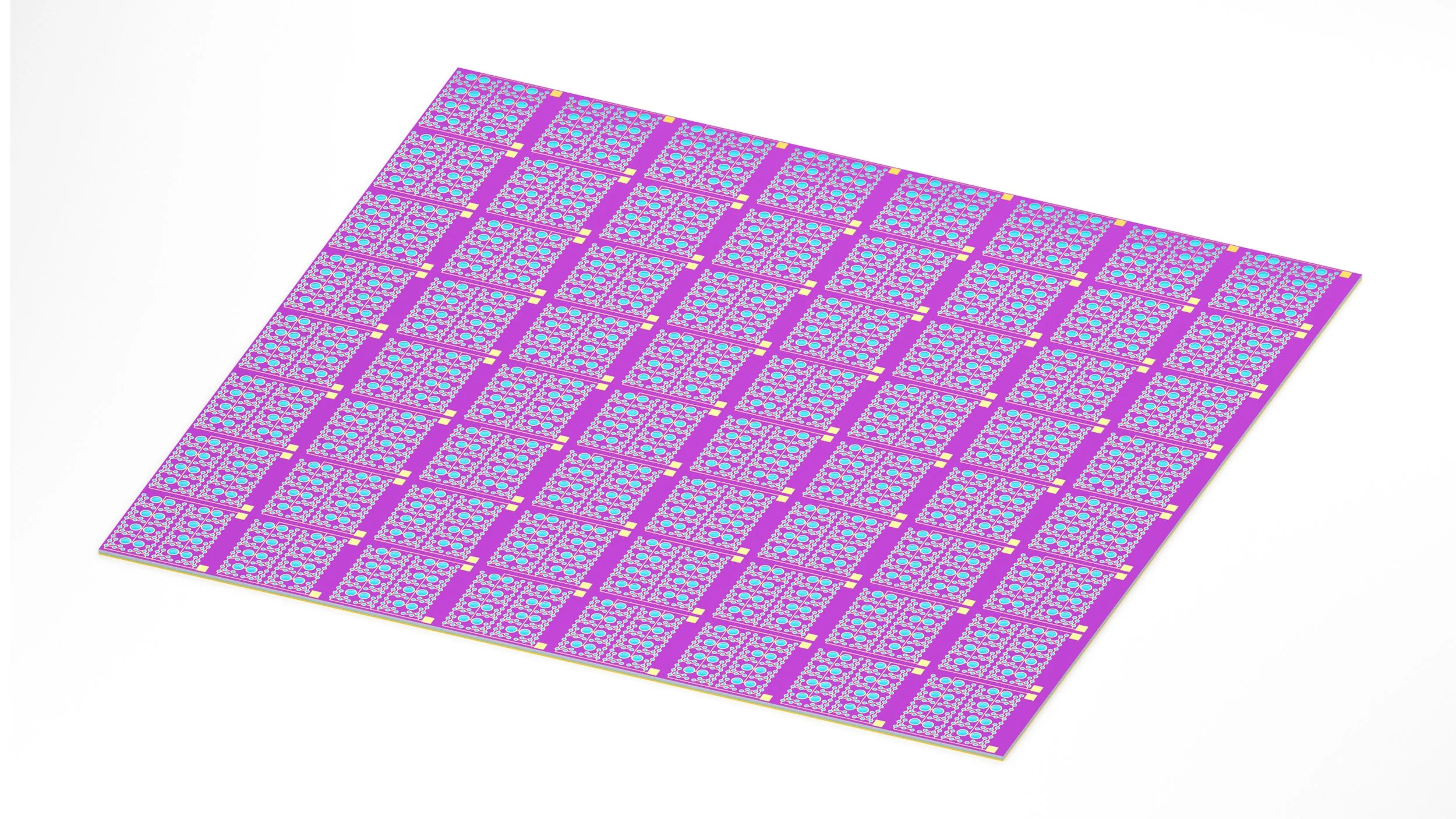

A VCSEL (Vertical Cavity Surface Emitting Laser) is a semiconductor laser diode that emits light perpendicular to the wafer surface rather than from the edge. This vertical emission makes it possible to test devices at the wafer level and to create dense, addressable arrays on a single chip.

Compared with conventional edge-emitting lasers, VCSELs offer:

Circular, low-divergence beams

Excellent wavelength and polarization stability

High modulation speeds

Low power consumption and long lifetime

2.2 How a High Power VCSEL Array Is Built

In a High Power VCSEL Array, many VCSEL emitters are integrated on one chip or within one module to deliver higher total optical power while maintaining very precise beam control. A typical Ace Photonics array solution combines:

Engineered substrates – Optimized GaAs substrates and supporting materials for mechanical stability and efficient thermal conduction.

Active laser regions – Carefully designed epitaxial structures to deliver target wavelengths in the 750–900 nm band, including commonly used 760, 790, 795, 890 and 895 nm options for sensing and quantum applications.

Vertical resonant cavities – Precisely controlled optical cavities to achieve narrow linewidth and high output efficiency.

Current confinement and thermal management structures – To maintain uniform emission across the array and support high output operation.

Array and integration technology – High-density emitter layouts and chip-level micro-optics, such as microlens arrays, to shape beams without large external optics.

These building blocks result in a compact, high-power, wavelength-stable light source that can be delivered as a die, TO-can, ceramic, SMD or custom package for direct use in industrial automation systems.

3. High Power VCSEL Array Applications in Industrial Automation

3.1 3D Sensing and Machine Vision

High Power VCSEL Arrays are widely used as illumination sources in 3D sensing and depth cameras. Structured light and ToF (time-of-flight) systems rely on stable, narrow-band infrared illumination to generate accurate depth maps. Our arrays are applied in:

Robot guidance and bin-picking

In-line dimensional inspection

Surface defect detection

Automated optical inspection (AOI) in electronics manufacturing

3.2 Precision Alignment and Positioning

In automated assembly lines, micrometer-level alignment is a must for tasks such as component placement, welding, and micro-assembly. High Power VCSEL Array modules provide:

Uniform, repeatable illumination for camera-based alignment

Low divergence beams for precise spot or line projections

High modulation speeds for synchronized measurement with motion systems

This enables robust, real-time feedback loops in modern motion control and positioning platforms.

3.3 Gesture, Object and Presence Detection

Using VCSEL-based illumination, smart factories can add intuitive human-machine interfaces and reliable safety features:

Gesture recognition for operator control panels

Presence and proximity sensing for safety zones

Object detection for conveyor and logistics systems

3.4 LiDAR and Range-Finding in Industrial Environments

High power arrays at near-infrared wavelengths are also used for short- to mid-range LiDAR and distance measurement in:

Autonomous mobile robots (AMRs) and AGVs

Warehouse and logistics automation

Crane and stacker guidance

Here, the combination of fast modulation and stable output power is key to robust performance under changing lighting and temperature conditions.

3.5 Beyond the Factory: Quantum & Biomedical Sensing

The same core VCSEL technology is also deployed in quantum sensing, biomedical monitoring and oxygen sensors, demonstrating the reliability and precision of the platform:

Non-magnetic VCSEL packages for atomic magnetometers and MRI environments

Wavelength-specific devices for optical oxygen sensors and biomedical systems

For industrial customers, this cross-domain experience translates to highly mature design, fabrication and test processes.

4. Key Advantages of High Power VCSEL Arrays from a Manufacturer’s Perspective

4.1 Energy Efficiency and Thermal Performance

VCSEL devices routinely achieve high wall-plug efficiency at room temperature. Combined with careful thermal design and wafer-level optimization, this allows arrays to deliver strong optical power while maintaining low electrical and cooling overheads—an important factor for energy-conscious factories.

4.2 Accuracy, Stability and Narrow Linewidth

Our High Power VCSEL Arrays are designed for:

Tight wavelength control over temperature

Narrow spectral linewidths suitable for spectroscopy and high-precision sensing

Stable output over long operating lifetimes

For industrial users, this translates into consistent measurement performance, fewer recalibrations, and improved quality control.

4.3 Compact, Flexible Integration

Ace Photonics offers VCSEL dies, TO-cans, ceramic packages, SMDs and custom module designs. This flexibility allows system designers to:

Mount arrays directly on PCBs as SMDs

Integrate pre-aligned modules with lenses and frequency-conversion optics

Choose non-magnetic packages for sensitive sensing environments

Adapt package footprints to existing mechanical designs

4.4 Fast Modulation and Real-Time Response

Fast rise and fall times, along with high-speed modulation capability, make VCSEL arrays ideal for:

High-frame-rate 3D sensing

Synchronous detection and lock-in measurement schemes

High-speed optical communication links within industrial equipment

This rapid response enables automation platforms to react quickly to process changes and maintain high throughput.

4.5 Non-Magnetic Packaging for Precision Sensing

For quantum sensors, MRI-compatible systems, and ultra-sensitive magnetic measurements, ferromagnetic materials within the laser package can degrade performance. Ace Photonics offers non-magnetic VCSEL packages that eliminate magnetic interference, improving accuracy and signal-to-noise for advanced sensing applications.

5. Why Partner with Ace Photonics for High Power VCSEL Arrays?

As a specialized VCSEL manufacturer, Ace Photonics combines device physics expertise with practical industrial experience:

Deep GaAs VCSEL know-how – Custom epitaxial and device structure design tuned to your wavelength, power and operating temperature requirements.

Advanced chip processing – ICP etching, wet oxidation and BCB processes for reliable, repeatable high-volume manufacturing.

Array and integration technology – Proven know-how in high-density arrays, beam shaping using microlens arrays, and module-level integration.

Harsh-environment capability – Experience from aerospace and quantum sensing projects, including non-magnetic packages and extended temperature operation.

We work closely with OEMs and research partners worldwide to adapt High Power VCSEL Array solutions to specific automation tasks, from pilot projects to commercial series production.

6. Moving Toward Smarter, Optics-Driven Factories

High Power VCSEL Arrays are reshaping how industrial systems sense, measure and interact with their environment. By combining compact form factors, high efficiency, wavelength stability and flexible packaging, this technology supports:

Smarter robots with accurate 3D vision

Faster, more reliable in-line inspection

Safer human–machine interaction through precise gesture and presence detection

New classes of quantum and biomedical sensors that can be deployed close to the production floor

For manufacturers seeking to upgrade or design next-generation automation platforms, partnering with a dedicated VCSEL supplier such as Ace Photonics ensures that the light source at the heart of your system is as robust and forward-looking as the rest of your design.

If you are planning a new sensing module or considering a migration to High Power VCSEL Array illumination, our engineering team can help evaluate wavelengths, packages and module configurations tailored to your industrial application.