Ace Photonics VCSEL Fabrication for the Next Wave of Photonics

At Ace Photonics, VCSEL fabrication means owning the complete flow—from GaAs epitaxy and wafer processing to final module test. We combine GaAs-based epitaxial growth, fine-line lithography, controlled oxide or implant confinement, and strict reliability screens to build VCSELs that hold optical power, modulation speed, and wavelength stability over long field lifetimes.

Whether you need a single emitter for a quantum sensor or a high-density array for 3D sensing or datacom, we build to your electrical, optical, and packaging requirements and support you from early NPI through high-volume production.

Why Ace Photonics for VCSEL Fabrication

Process Depth Under One Roof

Our VCSEL manufacturing line keeps critical steps tightly linked in one process flow:

GaAs MOCVD/MBE epitaxy with engineered DBR mirror stacks

Precise mesa patterning and ion implantation

Selective oxidation to form stable oxide apertures

Front- and back-end metallization tailored to your package and assembly scheme

This integrated VCSEL fabrication approach shortens iteration cycles and reduces variability between lots.

Design-to-Fab Co-Engineering

We work as an extension of your design team. Together we tune:

Aperture size and cavity length to hit your threshold current, divergence, and linewidth targets

Mode control and current spreading to keep beam shape and polarization consistent over temperature

Thermal paths—from chip metallization to submount—to meet your R_th and lifetime requirements

Drive and system constraints, so the VCSEL matches your driver IC, optics, and mechanical stackup

Quality You Can Ship

Our VCSEL fabrication flow is aligned with ISO 9001–style quality systems and statistical process control on critical steps such as epitaxy, oxidation, and lithography. Wafer-level LIV and spectral mapping allow early binning before singulation, so only devices that meet spec move into assembly and test.

Short Feedback Loops

For new designs, we support rapid mask spins and structured DOE lots. That lets you:

Lock in yield and uniformity early

Compare different oxide aperture sizes and cavity designs on the same wafer

De-risk performance before committing to volume tooling

Customized VCSEL Solutions

No two sensing stacks or optical links are exactly alike. Ace Photonics configures VCSEL fabrication around your application rather than forcing you into a fixed catalog.

Wavelengths for Sensing and Communications

Typical operating bands include the near-infrared regime used in:

Quantum and atomic sensing around rubidium and cesium transitions

3D sensing, facial recognition, and structured light

Short-reach datacom links and active optical cables

Within these windows we can fine-tune nominal wavelength and temperature behavior to match your filters and detectors.

Aperture and Cavity Engineering

We support a wide range of aperture diameters and cavity structures:

Oxide-confined apertures engineered for efficiency and mode control

Implant-confined structures where robustness and thermal headroom are paramount

Single-mode designs for narrow divergence and low noise

Multi-mode options for higher power and illumination applications

VCSEL Arrays

Ace Photonics manufactures both 1D and 2D VCSEL arrays, from a few emitters to large matrices with thousands of channels. We can provide:

Common-cathode or individually addressable layouts

Optimized pitch for diffractive or microlens optics

Consolidated pads and routing to simplify your PCB or flex design

Speed and Modulation

For datacom and short-reach fiber links, we target high-speed lanes with:

10 Gbps per lane as a baseline, with paths beyond 25 Gbps for advanced designs

Clean eye diagrams at operating temperature and bias

Fast rise/fall times for time-of-flight and pulsed systems

For sensing and ranging, we support pulsed operation, duty-cycled drive, and tailored modulation schemes that balance SNR, eye safety, and thermal load.

Packaging Options

Our VCSEL fabrication is paired with packaging routes such as:

TO-can and non-magnetic TO variants for quantum and precision sensing

SMD and chip-on-board assemblies for compact embedded designs

LGA/SMT substrates for high-density integration

Optics-integrated modules with microlenses or diffractive elements

Optional driver co-packaging for reduced parasitics and smaller footprints

VCSEL Fabrication Process at Ace Photonics

1. Epitaxy – Building the Optical Stack

We start with GaAs-based epitaxial growth of:

Lower and upper DBR mirrors

Quantum well active region

Confinement and current-spreading layers

Uniform epitaxy is central to threshold current, slope efficiency, and wavelength stability, so we control growth conditions and in-situ monitoring throughout the run.

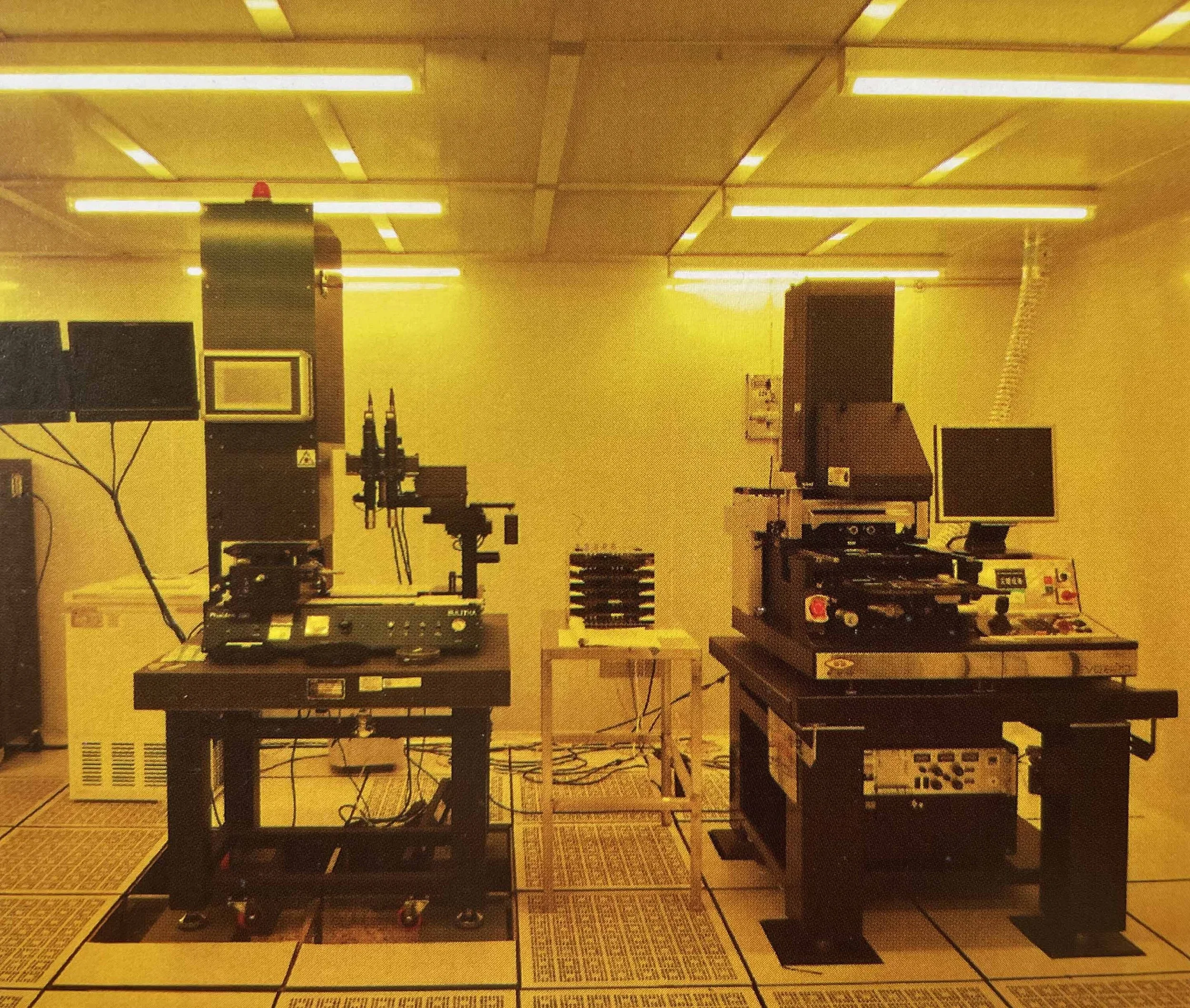

2. Photolithography – Defining Features and Arrays

Sub-micron lithography defines mesas, apertures, and array pitch. Tight control of critical dimensions helps:

Maintain consistent resistance and capacitance

Keep optical modes stable across the wafer

Align array emitters to downstream optical structures

3. Etching – Sculpting the VCSEL Structure

We combine dry and wet etch steps to form mesas and expose the correct layers for oxidation and contacts. Etch profiles are tuned to:

Protect DBR mirror integrity

Enable repeatable oxide aperture placement

Control sidewall quality for long-term reliability

4. Current Confinement – Oxide Aperture or Implant

We use selective wet oxidation and/or ion implantation to define the current path and optical aperture. This step directly impacts:

Mode behavior and divergence

Differential resistance and thermal performance

Robustness under high-temperature and high-current operation

5. Metallization – Contacts and Redistribution

Low-resistance ohmic contacts and redistribution layers are designed for:

Uniform current injection across each aperture or array

Strong ESD performance

Compatibility with Au-free or low-gold stacks when required by your package or assembly process

6. Passivation and Wafer-Level Characterization

Dielectric passivation protects mirrors, sidewalls, and edges from contamination and moisture. Before dicing, we perform wafer-level tests such as:

LIV sweeps for threshold and efficiency

Spectral and wavelength uniformity mapping

Far-field beam profile checks

Thermal rollover tests

These wafer-level tests allow early binning and traceability, reducing cost and risk in later assembly stages.

7. Dicing, Assembly, and Final Test

After singulation, dies are:

Die-attached to the selected submount or header

Wire-bonded or flip-chipped, depending on the package design

Encapsulated, sealed, or integrated into modules with optics and thermal management

We finish with environmental and reliability screens tailored to your market—for example, HTOL, temperature cycling, humidity testing, and mechanical robustness checks.

Advanced VCSEL Fabrication Techniques at Ace Photonics

To push performance further, Ace Photonics uses advanced optimization techniques throughout the VCSEL fabrication flow:

DBR mirror engineering for target wavelength, linewidth, and temperature drift

Uniformity control via in-situ epi monitoring and post-epi mapping

Thermal path design from chip to system level to flatten R_th and extend lifetime at power

Array co-optimization, including crosstalk control, beam shaping, and microlens alignment strategies

These measures are especially important for demanding applications such as quantum sensors, high-precision instruments, and automotive LiDAR.

What You Gain with Ace Photonics VCSELs

High performance – Strong wall-plug efficiency, low threshold, and stable wavelength under load

Reliability and longevity – Designs and screening focused on HTOL, temperature cycling, humidity exposure, and ESD robustness

Cost efficiency – Wafer-level binning and high yield at common wavelengths reduce system-level costs and simplify your supply chain

Applications We Support

Ace Photonics VCSEL fabrication underpins a wide set of markets:

Telecom & Datacom – Short-reach links, active optical cables, co-packaged optics, and backplane relief

Data Centers – 850-nm class links with tight skew, fast turn-on, and narrow spectral width for high-density switches and servers

Consumer Electronics – 3D sensing, proximity and gesture recognition, and eye-safe depth mapping

Automotive – LiDAR and ToF illumination sources, as well as driver and occupant monitoring (DMS/OMS) with extended temperature range requirements

Industrial & Medical – Positioning, flow sensing, oxygen monitoring, quantum and atomic sensing, and other instruments that rely on stable beam profiles and wavelength control

Case Study Highlights

High-Speed Datacom Refresh

A networking customer needed higher line rates without excessive thermal penalties in the transceiver. Working jointly, we:

Tuned oxide aperture diameter and placement for better differential resistance

Optimized mirror stack design for the desired wavelength and slope efficiency

Qualified a package with improved thermal conductivity and reduced R_th

The result was a VCSEL that maintained eye-diagram quality at the new data rate while improving wafer-level yield and tightening wavelength distributions.

Precision Medical and Quantum Sensing

A medical/quantum sensing OEM required narrow divergence and tightly controlled pulse energy for consistent measurements. Ace Photonics:

Produced a custom array with tightly controlled aperture diameters and spacing

Implemented wafer-level binning on optical power and wavelength

Verified far-field distributions and pulse stability across temperature

The final module delivered repeatable illumination from unit to unit, reducing calibration time and improving system-level SNR.

The Road Ahead: Trends in VCSEL Fabrication

Looking forward, several trends are shaping VCSEL fabrication:

PIC integration and co-packaging – Closer integration with drivers and silicon photonics to reduce loss and footprint

More complex arrays – Higher emitter counts, addressable patterns, and advanced beam shaping for structured light and scanning

Sustainable manufacturing – Greater emphasis on water recycling, solvent recovery, and energy-efficient tools to reduce fab environmental impact

Ace Photonics continues to evolve its VCSEL fabrication platform around these directions, while keeping compatibility with existing system architectures.

Frequently Asked Questions

What makes VCSELs from Ace Photonics suitable for automotive use?

Rugged oxide apertures or implant structures, carefully engineered metallization, and market-specific qualification (HTOL, temperature cycling, humidity, vibration) help keep optical and electrical performance stable across the full automotive temperature and stress range.

How do you control wavelength drift in VCSEL fabrication?

We combine DBR mirror design, epitaxial uniformity, and thermal path engineering. Devices are characterized near their real operating temperature, and binning strategies help keep modules consistent in volume production.

Can you support custom VCSEL arrays?

Yes. We can configure pitch, emitter count, grouping, and pad layouts. For optical stacks, we also support alignment to microlenses or diffractive elements to achieve the beam shape and field of view your system needs.

Do you provide wafer-level data?

We can supply wafer-level LIV, spectral maps, far-field data, and other key parameters. This traceability supports smarter binning, system-level modeling, and long-term quality tracking.