VCSEL 760nm: Transforming Gas and Exhaust Gas Temperature Sensor Technology

1. Introduction

Gas detection and monitoring have become essential across industries ranging from automotive safety to environmental control. One of the most significant breakthroughs supporting this progress is the Vertical-Cavity Surface-Emitting Laser (VCSEL). In particular, the VCSEL 760nm has emerged as a key innovation, delivering unparalleled sensitivity and reliability in modern gas sensors and exhaust gas temperature sensors.

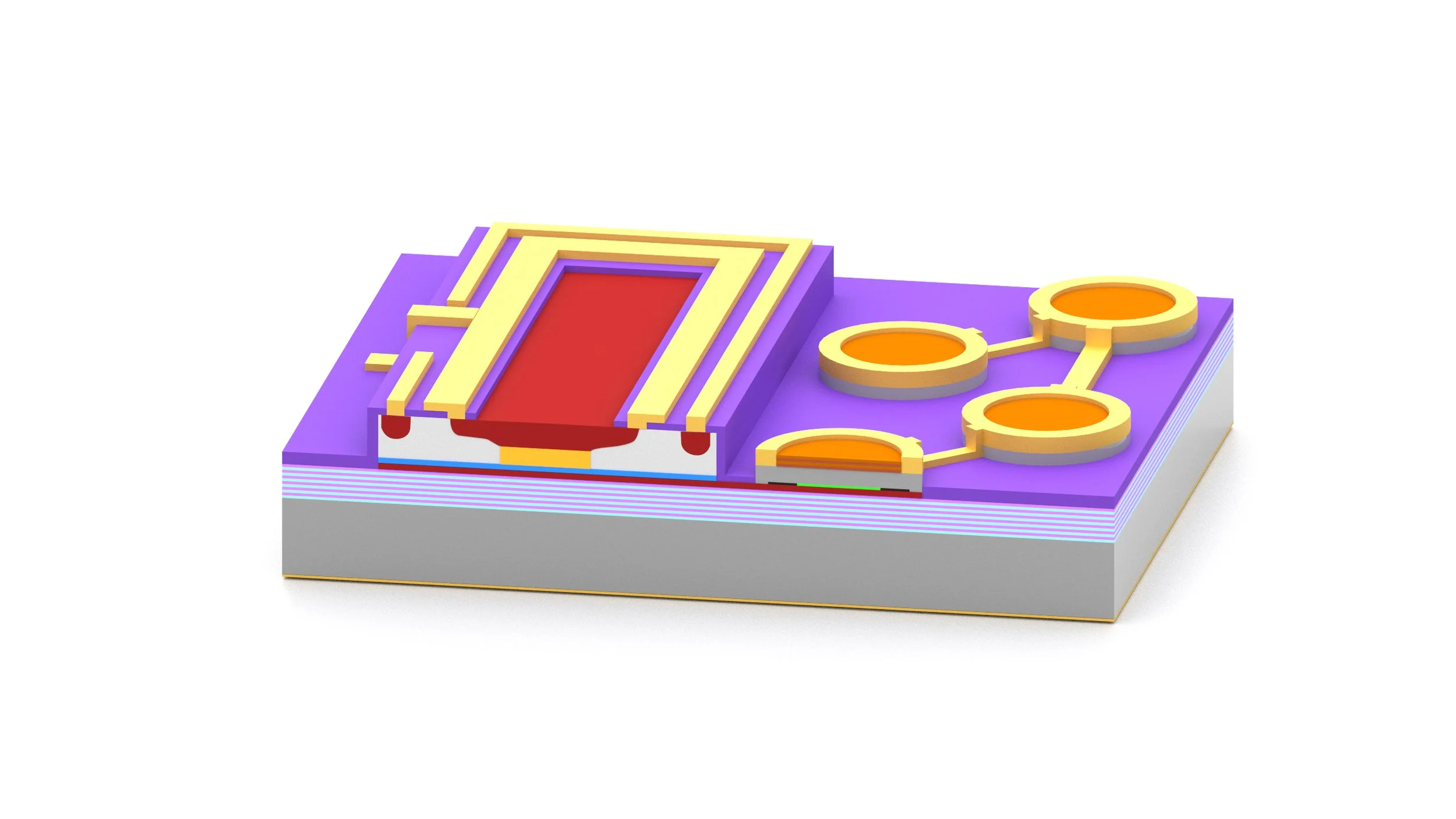

2. What is a VCSEL?

A VCSEL (Vertical-Cavity Surface-Emitting Laser) is a semiconductor laser diode that emits light vertically from its surface, unlike traditional edge-emitting lasers. This design provides several manufacturing and performance advantages:

Low power consumption – reducing energy requirements.

High modulation speed – enabling real-time sensing.

Wafer-level testing – ensuring high production yield and consistency.

For manufacturers, these advantages translate into lower costs and greater scalability for high-performance sensing solutions.

3. The 760nm VCSEL in Focus

The 760nm VCSEL emits light at a wavelength of 760 nanometers, a spectral region highly relevant for gas absorption detection. This makes it exceptionally effective in applications such as CO₂ monitoring, industrial emissions testing, and automotive exhaust gas sensors.

By targeting specific gas absorption bands, the 760nm VCSEL enables higher detection accuracy compared to conventional light sources.

4. Importance of Gas and Exhaust Gas Temperature Sensors

Industrial safety: Early leak detection prevents accidents and ensures regulatory compliance.

Environmental monitoring: Precise tracking of pollutants and greenhouse gases protects air quality.

Automotive systems: Advanced exhaust gas temperature sensors equipped with VCSEL 760nm technology optimize combustion efficiency, reduce emissions, and extend catalyst lifespan.

Medical diagnostics: Non-invasive monitoring of respiratory gases supports better patient outcomes.

5. How Gas Sensors Work

Gas sensors detect changes in electrical, chemical, or optical properties when exposed to gases. By integrating a VCSEL 760nm light source, the sensor can specifically measure gas absorption levels, converting them into precise data signals.

6. Role of 760nm VCSEL in Gas and Exhaust Gas Sensors

The adoption of VCSEL 760nm provides several technical benefits:

High stability: Offers a reliable light source with minimal drift.

Precision tuning: Aligns laser output with target gas absorption lines.

Improved accuracy: Reduces false readings and ensures consistent performance in demanding environments.

For exhaust gas temperature sensors, this wavelength allows highly sensitive detection of gases critical for combustion optimization and emission control.

7. Sensitivity and Selectivity

Enhanced sensitivity: Detects even trace concentrations of gases, enabling early detection.

Improved selectivity: Minimizes cross-interference by matching exact absorption bands, ensuring accurate measurements even in mixed-gas environments.

8. Key Applications of VCSEL 760nm in Gas Sensing

8.1 Industrial Safety

Leak detection in chemical plants.

Monitoring hazardous gases to comply with occupational safety standards.

8.2 Environmental Monitoring

Air quality measurement and greenhouse gas detection.

Real-time monitoring of industrial emissions.

8.3 Automotive Exhaust Systems

Exhaust gas temperature sensors equipped with VCSEL 760nm improve fuel efficiency and emission compliance.

Detection of combustion gases supports predictive maintenance and regulatory alignment.

8.4 Medical Diagnostics

Breath analysis for respiratory health monitoring.

Accurate detection of gases like oxygen and CO₂ in clinical environments.

9. Advantages of VCSEL 760nm for Gas Sensing

High precision – Detects gases at very low concentrations.

Cost efficiency – Lower power requirements and streamlined manufacturing reduce total system cost.

Scalability – Suitable for integration into compact sensor systems.

Customization – Manufacturers can tailor wavelength, packaging, and integration for diverse applications.

10. Manufacturer Perspective – Our Commitment

As a VCSEL manufacturer, we recognize the growing demand for 760nm VCSEL-based gas sensors and exhaust gas temperature sensors. Our production emphasizes:

High-quality wafer-level testing for reliable device performance.

Flexible customization to meet application-specific requirements.

Long-term stability for harsh industrial and automotive environments.

11. Future Trends

The next wave of gas sensing innovation will integrate VCSEL 760nm with AI-powered algorithms and IoT connectivity. This will enable:

Real-time emissions monitoring.

Predictive diagnostics in automotive exhaust systems.

Smart city environmental networks with enhanced air quality tracking.

12. Conclusion

The VCSEL 760nm is redefining the standards of gas sensing and exhaust gas temperature sensor technology. By delivering unmatched sensitivity, precision, and scalability, it is setting new benchmarks across industrial, automotive, medical, and environmental applications.

As leading VCSEL manufacturers, we continue to push the boundaries of this technology—driving safer, cleaner, and smarter solutions for a rapidly evolving world.