High-Power 795 nm VCSEL Arrays for Optical Communication

As optical communication moves deeper into data-driven and sensing-rich environments, system designers are looking for light sources that combine stability, efficiency, and easy integration. High-power 795 nm VCSEL (Vertical-Cavity Surface-Emitting Laser) arrays from Ace Photonics are engineered precisely for this kind of work—especially where optical communication must coexist with sensing, imaging, and quantum-related functions.

What Are VCSEL Arrays?

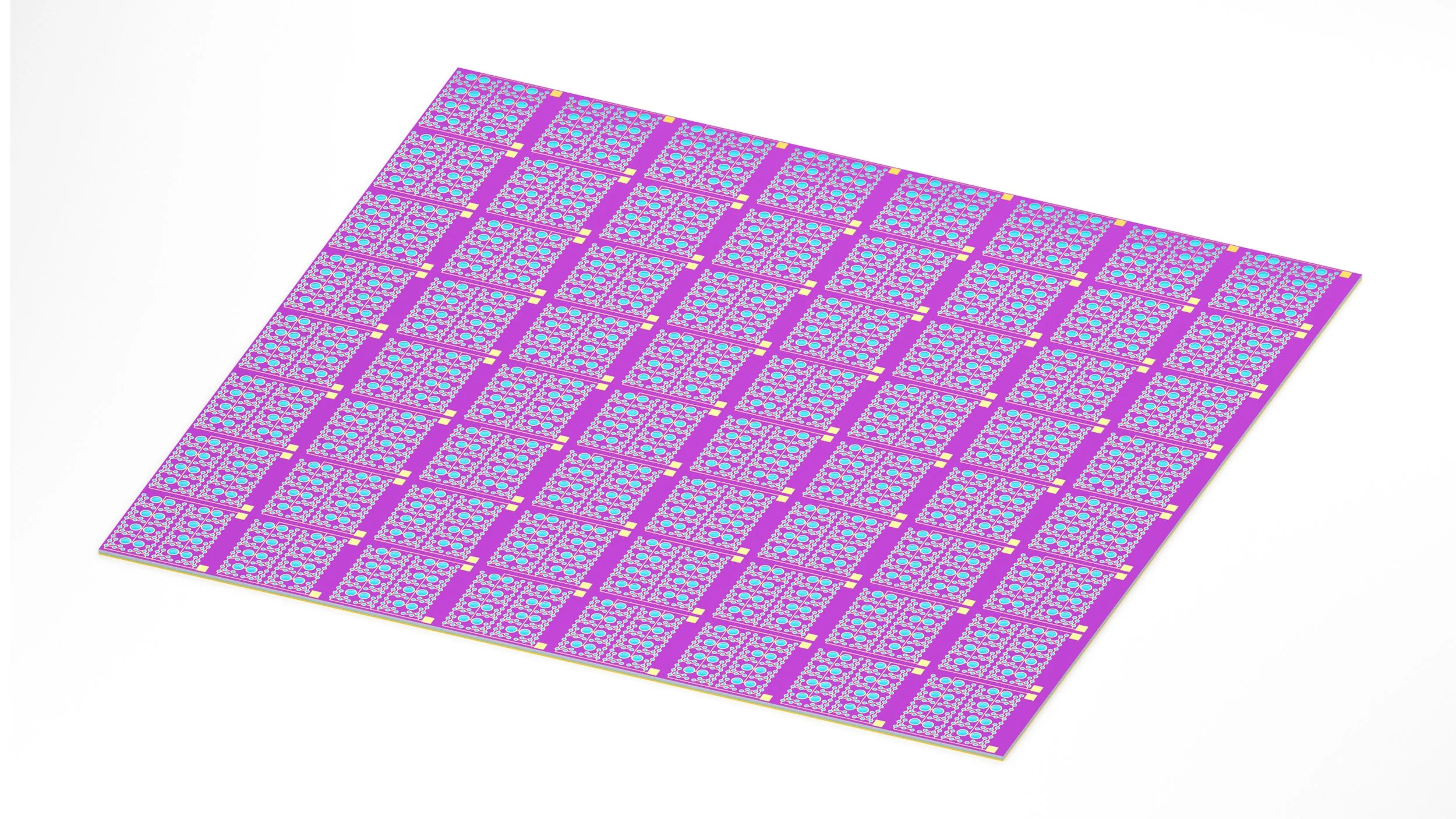

A VCSEL is a semiconductor laser that emits light vertically from the surface of the chip rather than from the edge. This surface-emitting architecture allows full wafer-level testing before dicing and packaging, improving yield and consistency across large volumes.

A VCSEL array is a group of VCSEL emitters arranged on the same chip or substrate and driven together or in segments. Compared with a single emitter, arrays offer:

Higher total optical power

Scalable beam profiles for free-space or fiber-coupled optical communication links

Fine control of beam shape using micro-optics and array design

Redundancy and flexibility in system-level design

This makes VCSEL arrays ideal light sources for compact optical communication modules, LiDAR, 3D sensing, and quantum and industrial systems where footprint and power budget are tightly constrained.

Why 795 nm Matters in Optical Communication

Ace Photonics focuses on high-performance VCSELs in the 750–900 nm band, including dedicated 795 nm devices that can be deployed in both sensing and short-reach optical communication scenarios.

The 795 nm wavelength is particularly attractive when:

Optical communication is tightly coupled to atomic or quantum media (e.g., rubidium-based sensors), where 795 nm aligns with key transitions and maximizes interaction efficiency.

Networks must combine data transmission and sensing in the same optical path, such as environmental or medical monitoring systems that also relay measurement data.

Designers need low background noise with IR bandpass filters while maintaining high signal-to-noise ratio and stable output over temperature.

By balancing absorption and penetration in many materials and media, 795 nm sources can support precise sensing and measurement while still enabling robust optical communication in specialized industrial and scientific systems.

Core Advantages of Ace Photonics VCSEL Arrays

Ace Photonics has built its VCSEL portfolio around GaAs-based devices with carefully engineered epitaxial structures and device designs.

High-power 795 nm VCSEL arrays from Ace Photonics offer:

Vertical resonant cavity structure for high efficiency and stable wavelength

Current confinement and thermal management for low power consumption and reduced heat

Polarization and wavelength control to maintain performance over a wide temperature range

Array and integration technology that scales from single emitters to high-power arrays

Symmetric, low-divergence beams, simplifying coupling into fibers or free-space optics

Fast rise and fall times, enabling high-speed modulation for optical communication links

Wafer-level manufacturing and testing, improving reliability and cost effectiveness

These technical foundations translate into VCSEL arrays that maintain performance in demanding environments, including aerospace payloads, quantum sensing platforms, and high-end industrial systems.

Optical Communication Applications

Although 795 nm is best known for quantum and sensing applications, it also plays an important role in specialized optical communication where the light source must interact efficiently with specific media or sensors while still carrying high-integrity data.

Short-Reach and Embedded Optical Links

High-power 795 nm VCSEL arrays can be used in:

Board-to-board and module-to-module optical links in high-end equipment

Free-space optical communication inside instruments and payloads, where fiber routing is difficult

Hybrid communication-and-sensing networks, such as instrument clusters that share the same light source for measurement and data backhaul

Their high modulation speed, low power consumption, and stable wavelength support reliable transmission while keeping size and thermal load under control.

Quantum-Aware Communication Systems

In quantum sensing and atomic instrumentation, VCSELs at 795 nm and 895 nm are used to pump or probe quantum media. When these systems need to transmit data optically (for example, from a sensor head to an electronics unit), using the same spectral region simplifies optical design and filtering strategies.

Ace Photonics also offers non-magnetic VCSEL packages, which are critical when optical communication hardware is placed near ultra-sensitive quantum sensors where stray magnetic fields must be minimized.

Beyond Communication: Sensing, Imaging, and Processing

Because 795 nm VCSEL arrays offer high beam quality and controllable power, they naturally extend from optical communication into several adjacent industrial domains.

Sensing Technologies

Ace Photonics VCSELs are already used in:

Environmental sensing and gas or oxygen monitoring, where wavelength-specific emission boosts sensitivity

Medical instrumentation, where stable near-infrared output supports non-invasive monitoring and diagnostics

3D sensing and facial recognition, where efficient arrays and integrated micro-optics generate structured or flood illumination patterns

In these systems, data from the sensors is often transmitted via optical communication links, so using 795 nm VCSEL arrays as both the light source and the communication carrier can simplify architecture and reduce component count.

Imaging Systems

High-power VCSEL arrays at 795 nm are also suitable for:

Industrial imaging, where controlled illumination improves defect detection and dimensional measurement

Medical imaging, where stable, narrow-band near-IR light supports tissue imaging or functional diagnostics

Again, integrating illumination, sensing, and optical communication around a common spectral region can streamline system-level design.

Material Processing and 3D Printing

For certain materials and resins, near-infrared sources like 795 nm VCSEL arrays can be used for:

Localized heating and curing in precision material processing

Additive manufacturing and 3D printing processes that rely on well-defined, controllable beams

The ability to scale array size and operating power makes it practical to tune illumination profiles to specific industrial workflows.

Customization and Design Flexibility

Ace Photonics positions itself as both a manufacturer and a design partner. The company draws on more than 20 years of semiconductor-laser expertise and offers extensive customization around VCSEL structure and packaging.

Tailored VCSEL Structures

For optical communication customers, Ace Photonics can customize:

Emission wavelength (e.g., 790/795 nm series)

Epitaxial and cavity design for specific linewidth or modulation requirements

Polarization control to improve coupling efficiency and signal-to-noise ratio

The product line includes 0.1 mW, 1 mW, and 1.8 mW 790/795 nm VCSEL die, which can be combined in arrays and packaged in SMD, TO-46, or non-magnetic formats depending on the target application.

Packaging and Modules for Easy Integration

To support fast integration into optical communication systems, Ace Photonics offers:

Bare VCSEL die for direct integration on custom boards or modules

VCSEL packages (including non-magnetic designs) optimized for quantum and precision sensing

VCSEL modules with integrated temperature controllers and sensors, simplifying thermal management

OEM-oriented solutions for aerospace and other special environments

These options help engineers align package style, thermal behavior, and optical interface with the rest of the communication or sensing platform.

Integration Support

Because many optical communication projects involve tight mechanical and environmental constraints, Ace Photonics provides engineering support for:

Optical coupling strategies (free-space, fiber, or waveguide)

Operating temperature range and thermal design

Selection of drive and control electronics, including TEC and thermistor integration

This level of collaboration makes it easier to move from concept to qualified product while maintaining signal integrity and long-term stability.

Technology Roadmap and Market Outlook

The demand for high-performance VCSELs is growing across quantum sensing, 3D sensing, optical communication, and high-end equipment. Ace Photonics has aligned its roadmap with this trend, focusing on:

Extending power levels of single-mode VCSELs while preserving narrow linewidth

Expanding the 750–900 nm product family, including 795 nm arrays for quantum-aware optical communication

Enhancing packaging platforms for harsh or space-constrained environments

Maintaining high quality through ISO 9001:2015-certified processes and rigorous testing

As industrial and scientific systems converge—combining sensing, computation, and communication in a single platform—795 nm VCSEL arrays are set to play an increasingly important role.

Conclusion

From a VCSEL manufacturer’s perspective, high-power 795 nm VCSEL arrays are not just light sources; they are enablers of tightly integrated optical communication, sensing, and imaging architectures.

With wafer-level surface emission, excellent wavelength stability, low power consumption, and flexible packaging, Ace Photonics VCSEL arrays provide a robust foundation for:

Specialized optical communication links tightly coupled to sensors or quantum media

High-precision industrial and medical instrumentation

Advanced imaging, 3D sensing, and material-processing systems

By combining deep GaAs VCSEL expertise, customizable device structures, and strong integration support, Ace Photonics helps designers unlock the full potential of 795 nm VCSEL arrays in next-generation optical communication and industrial applications.