Advancements in VCSEL Manufacturing Processes

At Ace Photonics, we focus on the design and manufacturing of high-performance VCSEL arrays for sensing, communication, and industrial applications. By continuously refining our processes and equipment, we help customers integrate reliable, energy-efficient VCSEL array solutions into their products at scale.

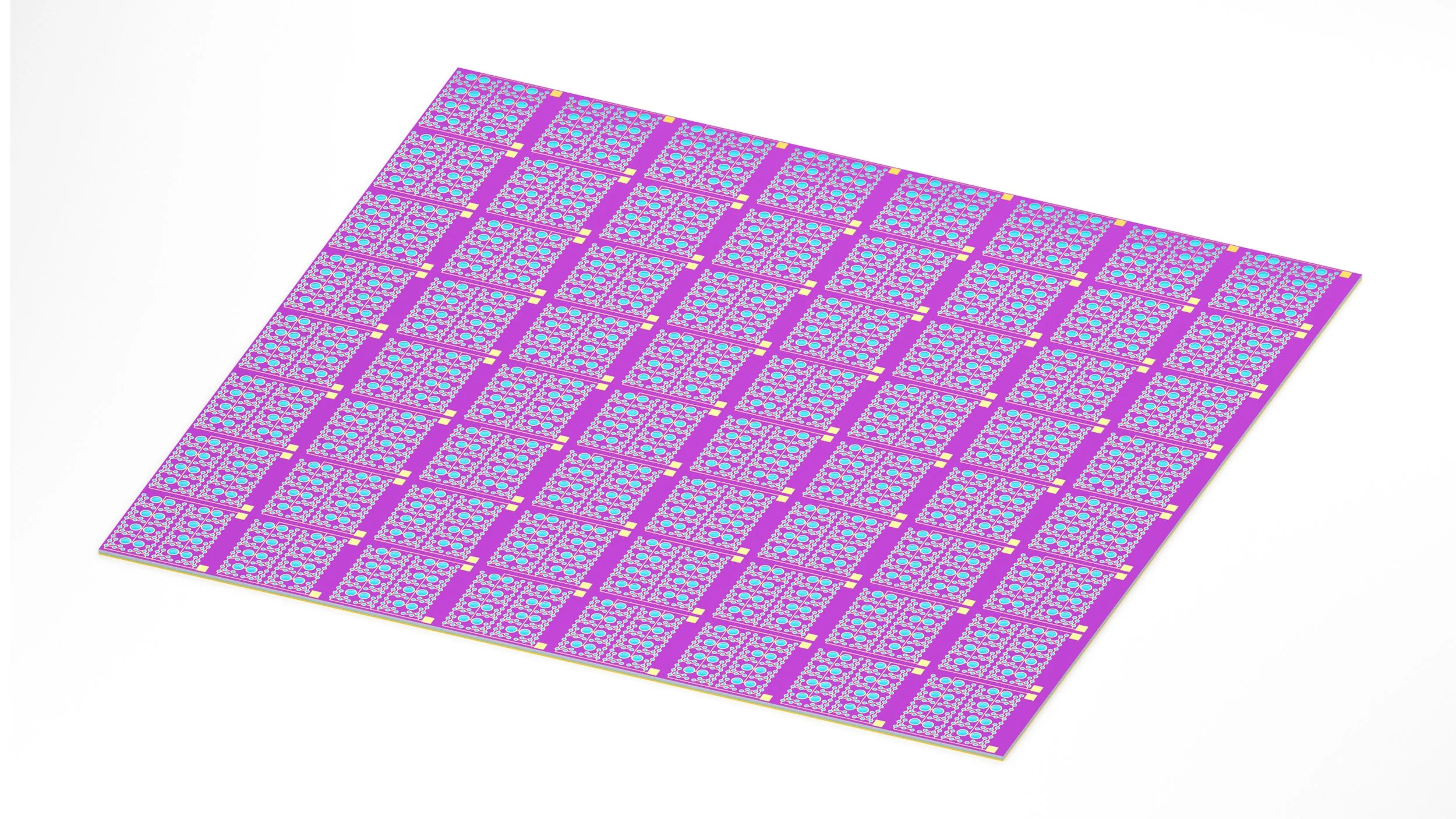

Understanding VCSELs and VCSEL Arrays

VCSELs (Vertical-Cavity Surface-Emitting Lasers) are compact semiconductor lasers that emit light perpendicular to the surface of the chip. Because of their small footprint, low power consumption, and high reliability, VCSELs are well suited for integration into modern electronic and optoelectronic systems.

When multiple VCSEL emitters are arranged in a structured pattern, they form VCSEL arrays. These arrays can be:

Precisely aligned in grid structures for uniform illumination or sensing

Designed as etched VCSEL arrays to achieve specific beam shapes, densities, or optical characteristics

Optimized for applications where multiple beams or higher optical power density are required

For many customers, a grid-type VCSEL array is ideal because their application—such as structured light, LiDAR, or 3D sensing—demands a well-defined spatial pattern.

Advancements in VCSEL Array Manufacturing

As a VCSEL array manufacturer, Ace Photonics has invested heavily in process optimization and equipment upgrades. Our goal is straightforward: deliver VCSEL arrays with higher output power, better efficiency, and long-term stability, while keeping production costs competitive.

1. Enhanced Efficiency and Power Output

By refining epitaxial growth, wafer processing, and optical design, we have improved the optical efficiency of our VCSEL arrays. This leads to:

Higher output power at the same drive current

Reduced overall power consumption at the system level

Lower thermal load, which supports longer device lifetime

These improvements make our VCSEL arrays well suited for power-sensitive systems, portable devices, and high-density optical modules.

2. Improved Performance and Wavelength Stability

We also focus on performance consistency across arrays and over time. Our manufacturing processes are designed to:

Minimize optical and electrical loss across the array

Improve wavelength stability under varying temperature and operating conditions

Ensure reliable operation in demanding environments such as automotive, industrial, and outdoor systems

This stability is particularly important for applications such as telecommunications, LiDAR, and 3D imaging, where small variations in wavelength or power can affect system accuracy and range.

Custom VCSEL Arrays to Match Customer Requirements

Every customer’s system has different constraints, so we provide tailored VCSEL array solutions rather than a one-size-fits-all approach. Our engineering teams can collaborate on:

Adjusting output power and power density

Optimizing pulse characteristics, modulation behavior, and beam profile

Selecting package types (e.g., chip-on-board, surface-mount, or custom modules) for specific integration needs

This customization ensures that each VCSEL array not only meets optical and electrical requirements, but also integrates smoothly into the customer’s mechanical and thermal design.

Reliable Packaging to Overcome Process Challenges

VCSEL manufacturing involves tight process control. Any variation can impact device performance or reliability. To address this, Ace Photonics:

Closely monitors critical process parameters during fabrication

Performs thorough in-line and final testing on VCSEL arrays

Utilizes robust packaging solutions that protect against moisture, contamination, and mechanical stress

By combining advanced processing with reliable packaging, we ensure our VCSEL arrays comply with rigorous quality standards across different industries.

Competitive Cost Through Scaled Production

We understand that cost is a key factor when selecting VCSEL array manufacturers. Ace Photonics continuously works to:

Scale production volumes to lower the unit cost

Streamline process steps and improve yield

Maintain a balance between cost efficiency and performance quality

The result is a portfolio of VCSEL arrays that remain competitively priced without compromising on reliability or optical performance.

High-Power VCSEL Arrays for Bandwidth-Intensive Applications

For applications that demand high data throughput or long sensing range, we provide high-power VCSEL arrays capable of:

Supporting high transmission rates in optical communication and data links

Delivering sufficient optical power for long-range LiDAR and 3D sensing

Operating in pulsed or continuous modes depending on system design

These arrays are suitable for bandwidth-intensive and performance-critical applications, where both speed and stability matter.

VCSEL Arrays for Sensing and LiDAR Systems

VCSEL arrays are increasingly used in sensing and scanning systems due to their accuracy and compactness. Our arrays are designed for:

3D sensing (e.g., facial recognition, depth mapping, gesture detection)

Automotive LiDAR for advanced driver assistance and autonomous driving

Industrial sensing in automation, robotics, and safety monitoring

Ace Photonics provides compact and rugged VCSEL array modules that can withstand harsh environments, supporting engineers who are building next-generation sensing platforms.

Future Development of VCSEL Arrays at Ace Photonics

Looking ahead, we see significant potential for further innovation in VCSEL array technology. Our roadmap includes:

Exploring new device architectures and beam-shaping techniques

Further improving energy efficiency and lifetime

Developing more flexible array layouts and packaging options for emerging applications

As technology evolves, Ace Photonics remains committed to pushing the limits of what VCSEL arrays can do—offering customers more efficient, reliable, and application-specific solutions.