From Concept to Reality: VCSEL Chip in Consumer Electronics

As consumer devices get thinner, smarter, and always connected, the choice of light source inside each sensor matters more than ever. From smartphones and smartwatches to AR/VR headsets, a compact and efficient VCSEL chip often sits at the heart of depth sensing, biometrics, and short-range data links.

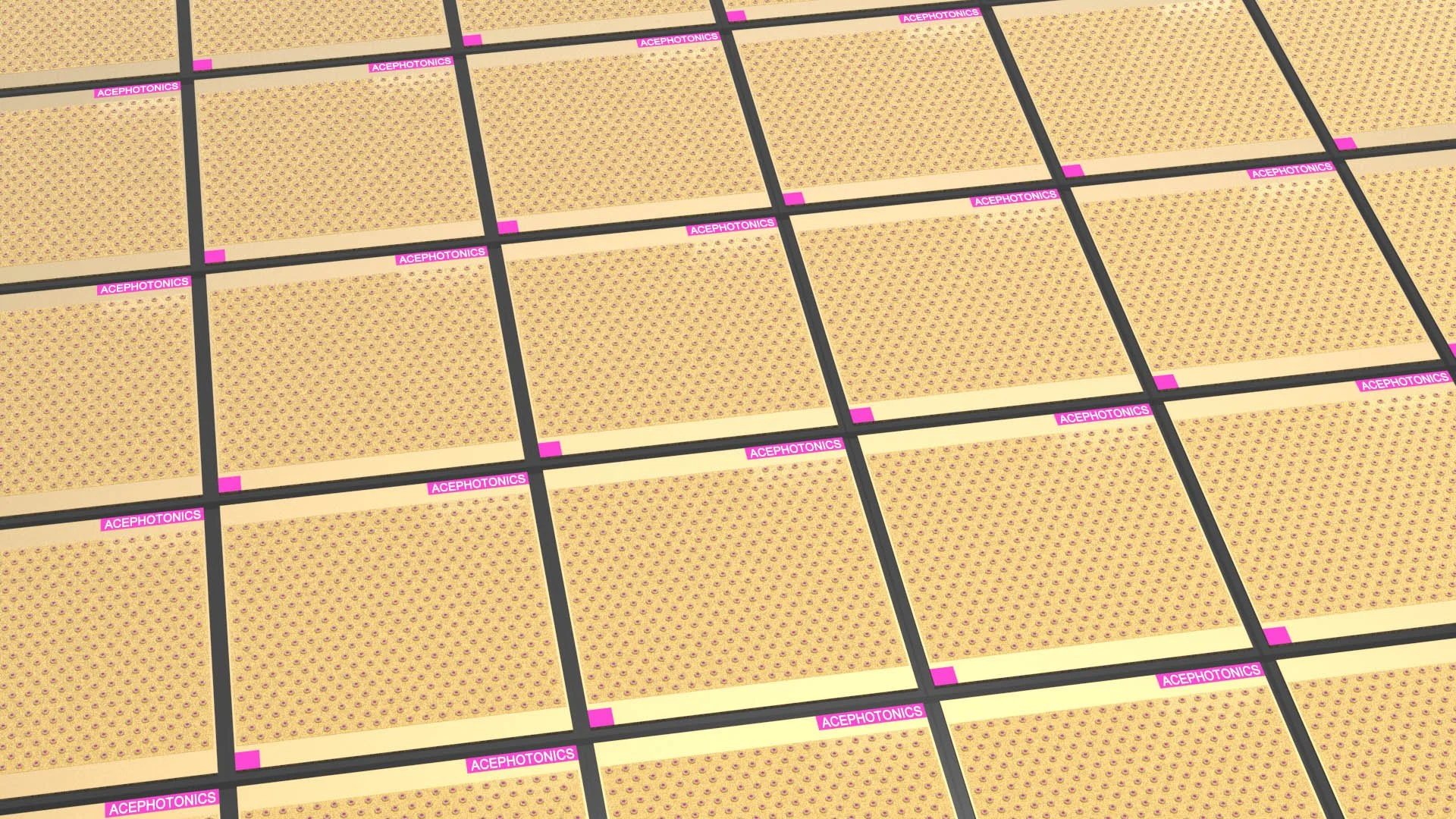

Ace Photonics, a dedicated VCSEL manufacturer, designs and fabricates VCSEL chips, die, and modules that help device makers turn optical concepts into reliable, mass-produced products.

What Is a VCSEL Chip?

A VCSEL chip is a semiconductor laser that emits light vertically from the surface of the wafer, rather than from the edge of the die like a traditional edge-emitting laser. This vertical-cavity design allows:

Surface (vertical) emission for easier coupling into optics and sensors

Wafer-level probing before dicing, which helps control cost and yield

Straightforward formation of 1D and 2D emitter arrays in a compact footprint

Because of their stable wavelength, good beam quality, and high efficiency, VCSEL chips combine many of the advantages of traditional semiconductor lasers with the manufacturability of LEDs, making them ideal for large-volume consumer electronics.

Where VCSEL Chips Show Up in Consumer Electronics

VCSEL chips now underpin many “invisible” features that end users take for granted. Typical use cases include:

Smartphones and Tablets

3D facial recognition and attention detection using structured light or ToF systems

Proximity sensing to control screen on/off behavior during calls

Laser autofocus to support fast, low-light focusing in camera modules

Wearables and Health Devices

PPG (photoplethysmography) for heart-rate and SpO₂ tracking

Fitness and wellness analytics powered by stable, narrow-band emission that improves signal quality on different skin tones and under motion

AR/VR/MR and Gaming

Depth mapping and hand tracking with VCSEL arrays projecting structured patterns for precise 3D sensing

Room-scale awareness for immersive gameplay and mixed-reality experiences

Smart Home and IoT

Gesture and presence detection in smart speakers, TVs, and appliances

Short-range optical links where low power and compact form factor are critical

The Evolution of VCSEL Chips in Devices

VCSELs started as niche components for data communications but quickly migrated into 3D sensing and biometrics once their efficiency, array scalability, and wafer-level testability were recognized by consumer OEMs.

Today, VCSEL chips are:

Smaller and more power-efficient, suited to battery-driven devices

Available across key NIR wavelengths (commonly around 850–940 nm) used in depth cameras and health sensors

Optimized for mass production, with tight binning and robust reliability data

Ace Photonics contributes to this evolution with high-power and single-mode VCSEL platforms that deliver stable wavelength and polarization over a wide temperature range—important for devices that must work reliably from a winter street to a hot dashboard.

Ace Photonics VCSEL Chips: From Die to Modules

Ace Photonics covers the full VCSEL chip value chain to support different integration levels:

VCSEL Die and Gain Chips

GaAs-based VCSEL die engineered for consumer and industrial wavelengths

Gain chips optimized for use in custom optical assemblies

Wafer-level testing to control threshold current, output power, and wavelength spread

VCSEL Packages

TO-can, SMD/LGA, and non-magnetic package options for various environments

Package designs that simplify automated pick-and-place and reflow processes

Options tailored for data communications, 3D sensing, biomedical sensing, and gesture recognition

VCSEL Modules

Integration of VCSEL chip, lens sets, and optional frequency-conversion optics

Ready-to-use laser modules for applications such as 3D sensing, laser processing, and medical devices

This portfolio allows consumer electronics manufacturers to choose the right level of integration—bare VCSEL chip, packaged device, or full module—depending on their internal optics and assembly capabilities.

Customization and Co-Design With Consumer OEMs

From the perspective of a VCSEL producer, no two consumer devices are truly identical. Ace Photonics therefore emphasizes custom VCSEL chip design and co-engineering with OEM teams.

Typical customization options include:

Wavelength and power level matched to the target sensor and optical stack

Emitter aperture size and layout for specific dot patterns or illumination geometries

Thermal design and packaging tuned for tight spaces and sealed housings

Array configurations for higher optical power or multi-function sensing (e.g., combined proximity and depth)

By engaging early in the design cycle, Ace Photonics helps device makers balance optical performance, eye-safety limits, battery life, and overall system cost.

Collaboration Across the Ecosystem

Successful deployment of VCSEL chips in consumer electronics requires cooperation between:

VCSEL manufacturers

Camera and sensing module suppliers

ASIC and driver designers

System OEMs and contract manufacturers

Ace Photonics works with research groups, semiconductor partners, and device makers worldwide, combining chip-level expertise with system-level feedback to refine each new VCSEL generation.

Regulatory Compliance and Reliability

Because VCSEL chips are laser devices, consumer deployments must respect eye-safety and electromagnetic compatibility standards. Ace Photonics supports customers by:

Designing VCSEL chips and modules to operate within defined IEC/EN laser safety classes

Providing characterization data for optical power, wavelength, and thermal behavior

Leveraging in-house testing processes refined through aerospace-related payload development and harsh-environment projects

This approach helps OEMs move more quickly through qualification and regulatory reviews.

Example Outcomes With VCSEL Chips

While individual customer programs remain confidential, typical improvements reported when shifting to a tailored VCSEL chip solution include:

Higher 3D-sensing accuracy versus generic emitters, improving unlock reliability and gesture detection

Reduced power consumption at the same sensing performance, extending battery life in mobile and wearable devices

More compact optical modules, freeing space for additional sensors or larger batteries

These benefits stem from matching the VCSEL chip characteristics—wavelength, beam shape, array geometry, and thermal performance—to the exact constraints of the product.

Future Prospects: VCSEL Chips in Next-Generation Devices

Looking ahead, VCSEL chips are expected to play a central role in:

AR/VR and spatial computing – denser arrays and improved beam control for higher-resolution depth maps

Edge AI and smart IoT – always-on sensing with ultra-low duty cycles and sub-milliwatt idle budgets

Advanced health and biomedical systems – multi-wavelength VCSEL chips, including UV variants, for more precise diagnostics and therapies

Automotive and mobility – cabin monitoring, driver attention sensing, and short-range LiDAR-style sensing

As these markets mature, the demand for customized, reliable VCSEL chips and modules will continue to grow.

Conclusion: Turning VCSEL Concepts Into Real Products

VCSEL chips have moved from research labs into millions of consumer devices, enabling 3D sensing, secure biometrics, health monitoring, and immersive user experiences. For electronics manufacturers, the challenge is no longer whether to adopt VCSEL technology, but how to integrate the right VCSEL chip into a competitive, scalable product.

With its focus on VCSEL die, packages, and modules, and its experience in custom chip and epitaxial design, Ace Photonics offers a complete path from early optical concept to mass-produced consumer hardware.

For OEMs planning the next generation of smartphones, wearables, AR/VR devices, or smart home products, partnering with a specialized VCSEL manufacturer is a direct way to turn optical innovation into market-ready reality.