Enhancing Optical Sensing with Precision VCSEL Diode Laser

Optical sensing looks simple from the outside—shine light, read a signal, calculate a result. In real systems, it’s rarely that clean. Ambient light drifts, materials vary by lot, optics pick up speckle and stray reflections, and temperature swings quietly nudge your readings. That’s why the light source matters so much.

At Ace Photonics Co., Ltd., we build VCSEL technologies for sensing teams that need repeatable measurements, compact designs, and a path from prototype to volume. Our VCSEL diode laser solutions scale from single emitters to dense arrays, with packaging options designed for real hardware constraints.

Why Optical Sensing Is Moving Past LEDs

LEDs helped make optical sensors affordable and widely deployed, but many modern sensing methods demand more control than an LED can comfortably deliver. In practice, LEDs often introduce tradeoffs:

broad spectral output that complicates filtering and selectivity

wider, less controlled emission that can waste optical budget

reduced measurement repeatability when you need tight wavelength behavior

A VCSEL diode laser is built for the opposite: narrowband output, strong directionality, and better stability for precision sensing setups—especially when you need a consistent beam profile and reliable system calibration.

What Makes a VCSEL Diode Laser Different

A VCSEL (Vertical-Cavity Surface-Emitting Laser) emits light vertically from the chip surface, rather than from a cleaved edge like an edge-emitting laser. That single design choice unlocks several practical advantages for sensing products:

Vertical emission that simplifies scaling

VCSELs are naturally suited to arrays—you can design dense emitters for uniform illumination, structured light, or segmented control without reinventing your optical architecture.

Wafer-level testing that supports volume consistency

Because VCSELs emit from the surface, they support wafer-level probing/testing before dicing and packaging, which helps improve yield control and consistency—exactly what sensor OEMs care about when shipping at scale.

Beam geometry that plays well with optics

Many sensing systems benefit from the VCSEL’s typically more symmetrical output behavior, which can reduce complexity in collimation, diffuser selection, or coupling strategies (depending on your emitter/array design).

Optical Performance Metrics That Actually Matter in Sensing

When engineers evaluate a VCSEL diode laser for optical sensing, the headline “power” number isn’t enough. Here are the parameters that most directly shape measurement quality and system robustness:

1) Center wavelength and wavelength stability

Stable wavelength behavior helps keep your optical model valid across temperature and time—especially for filtered receivers and wavelength-selective sensing principles. Ace Photonics commonly supports key sensing bands such as 850 nm and 940 nm, and offers broader customization by application needs.

2) Spectral behavior (linewidth / spectral width)

For applications like spectroscopy or selective absorption sensing, tighter spectral output can make calibration easier and improve sensitivity to small changes.

3) Beam profile and uniformity

Uniform illumination is a silent “multiplier” in ToF/3D sensing, imaging, and metrology. The cleaner the intensity distribution, the less your algorithms need to fight non-ideal optics.

4) Beam divergence

Lower divergence helps maintain usable spot size and signal strength over distance—useful for standoff measurements, alignment tolerance, and optical efficiency.

5) Modulation capability

Many sensing architectures rely on fast modulation (ToF, structured light patterns, coded illumination). VCSEL platforms are widely used where high-speed modulation and compact integration are priorities.

6) Package-driven thermal performance

Thermal design isn’t a footnote. Junction temperature impacts output, lifetime, and stability. Package choice (SMD vs TO-can vs custom) changes your thermal path and assembly flow—so it should be treated as a system-level decision, not just procurement.

Integration Best Practices for Real Products

A VCSEL diode laser is only as good as the way it’s integrated. These are the choices that typically decide whether a sensing module feels “effortless” or “fragile” in the field:

Optics: lensing, diffusers, and beam shaping

For uniform illumination: consider array geometry plus optical elements that smooth hotspots

For structured light / ToF: match emitter layout, optics, and receiver FOV early

For compact modules: chip-level or module-level optics can reduce external bulk (design-dependent)

Electronics: drivers and control

Stable, clean drive signals reduce noise and keep modulation consistent—especially when sensors run near eye-safety limits or across wide ambient conditions.

Compliance and safety

Many sensing products must consider laser safety requirements (e.g., IEC 60825-1) during design, not after mechanical layout is frozen.

Where VCSEL Diode Lasers Shine in Optical Sensing

Environmental and gas sensing

Tunable wavelength selection lets teams align emission with absorption features of target gases (system-specific), supporting more selective detection approaches.

Industrial process control and metrology

In production lines, repeatability is money. VCSEL-based sensing can support thickness checks, distance measurement, and real-time monitoring where drift and inconsistency create scrap and rework.

Medical and wearable sensing

Wearables and compact medical devices often demand low power consumption, small form factor, and stable optical output—strengths commonly associated with VCSEL platforms used in modern sensing.

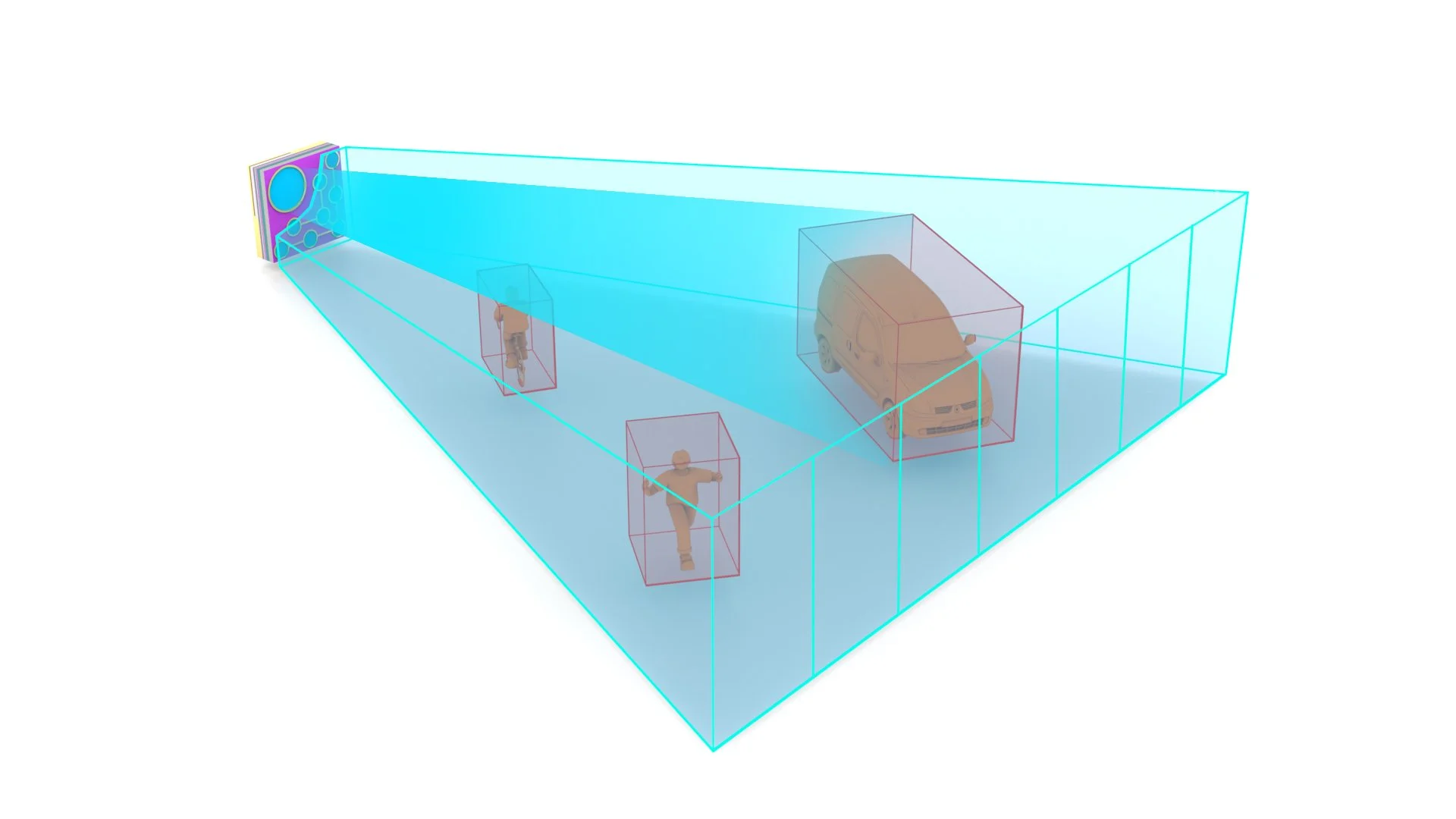

Automotive and mobility sensing

VCSEL-based illumination is widely used in 3D sensing and near-field ranging use cases, including in-cabin monitoring and short-range ToF architectures (system-dependent).

How Ace Photonics Supports OEMs and Integrators

We don’t treat “VCSEL diode laser” as a one-size product. We support different build paths depending on where you are in development:

VCSEL die for customers building their own optics or custom modules

Packaged VCSEL solutions including SMD and TO-style formats for manufacturable assembly flows

Single emitters or arrays, including solutions aimed at structured light and ToF illumination

Wavelength customization across a broad range for sensing-driven spectral needs (application-dependent)

If your team is balancing optical performance, mechanical constraints, and scale-up risk, we’ll usually start by aligning on: target wavelength, optical budget, thermal environment, packaging limits, and the measurement method (ToF, spectroscopy, imaging, etc.). Then we match die/array/package options accordingly.

A Practical Supplier Checklist (What to Ask Before You Commit)

When choosing a VCSEL diode laser supplier for sensing, these questions save time later:

Can they support your wavelength band and packaging constraints (SMD/TO/custom)?

Do they have a clear route from prototype parts to production consistency (wafer-level test, repeatable bins)?

Can they support arrays/modules if your roadmap expands from single emitter to illumination engine?

Will they help with integration details (drivers, thermal, optics) instead of only quoting a component?

Ready to Spec a VCSEL Diode Laser for Your Sensing System?

If you share your sensing method (ToF, structured light, spectroscopy), target wavelength, required output power, packaging preference (SMD or TO), and thermal environment, we can recommend a VCSEL diode laser configuration that fits your optical budget and manufacturing plan—without forcing you into a generic part that only works “in the lab.”