VCSEL Laser Array: Technology, Applications & Market Insights

What Is a VCSEL Laser Array?

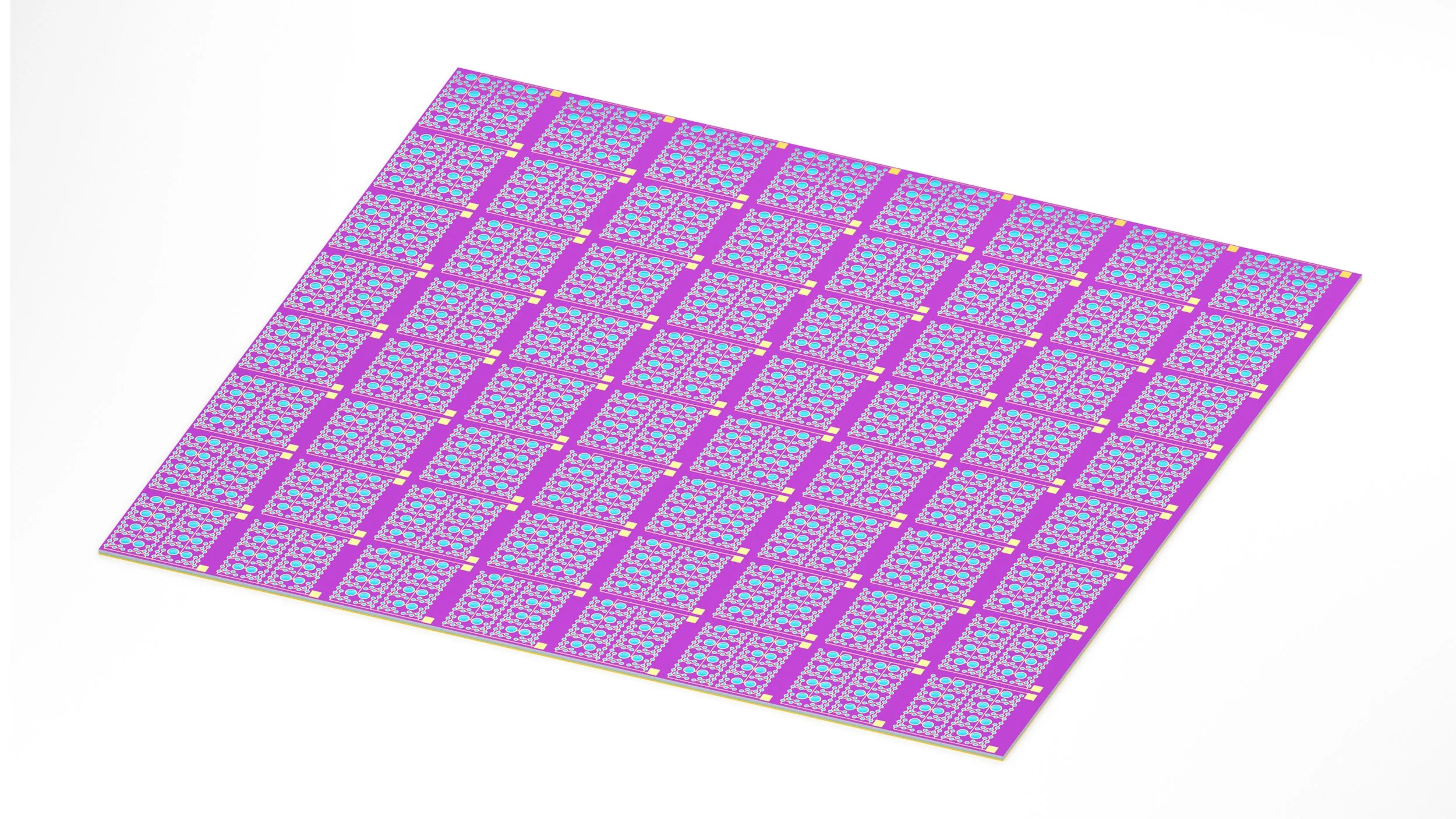

A VCSEL (Vertical-Cavity Surface-Emitting Laser) laser array is a semiconductor chip that integrates many tiny VCSEL emitters on one surface. Each emitter produces a narrow, stable beam, and together they form a dense, controllable light source.

Unlike edge-emitting lasers, a VCSEL laser array emits vertically from the wafer surface. This architecture offers:

Efficient coupling into fibers, waveguides and free-space optics

Low power consumption and high wall-plug efficiency

Excellent wavelength stability over temperature

Simple testing at wafer level, supporting high-volume production

For manufacturers and system integrators, this means scalable optical power, compact footprints and reliable performance in demanding environments.

How Does a VCSEL Laser Array Work?

Inside a VCSEL laser array, each pixel consists of multiple epitaxial layers grown on a GaAs wafer. The active region is sandwiched between distributed Bragg reflector (DBR) mirrors that form a vertical resonant cavity.

When current is injected:

Electrons and holes recombine in the active region.

Photons are generated and amplified within the cavity.

The DBR mirrors confine the light and force it to oscillate at a defined wavelength.

Coherent laser light exits perpendicularly from the top surface.

By arranging many of these emitters into a grid, ring or custom pattern, a VCSEL laser array can deliver:

High optical power density

Uniform illumination for structured light or ToF systems

Fast modulation for data links and high-speed sensing

Ace Photonics optimizes epitaxial design, current confinement and thermal paths so that each array maintains stable output across temperature and long-term operation.

Evolution of VCSEL Technology

VCSEL concepts were explored in the 1970s, and commercial devices began to scale in the 1990s with the rise of short-reach optical communication. Since then, VCSELs have become a core light source in:

Data center interconnects and optical backplanes

3D sensing for smartphones and consumer devices

Automotive and industrial LiDAR

Medical diagnostics and quantum sensing

Modern VCSEL laser arrays benefit from mature GaAs processing, precise wet oxidation and advanced etching techniques, enabling:

Narrow spectral linewidths

High reliability and long lifetimes

Wafer-level binning and cost-effective mass production

Ace Photonics builds on more than 20 years of VCSEL R&D experience, focusing on high-temperature, single-mode and non-magnetic solutions for specialized markets such as quantum applications and industrial automation.

Key Applications of VCSEL Laser Arrays

1. Optical Communication and Data Centers

VCSEL laser arrays are widely used in short-reach and medium-reach optical links:

High-speed data center interconnects

Optical backplanes and active optical cables

5G and edge-computing connectivity

Their benefits include:

Multi-gigabit data rates with low drive currents

Efficient coupling to multimode fibers

Low power consumption and reduced thermal load in racks

By integrating VCSEL arrays with driver ICs and passive optics, data center operators can upgrade bandwidth while controlling power and cooling budgets. Ace Photonics develops VCSEL dies and modules with stable wavelengths for robust, high-density communication links.

2. Sensing, LiDAR and 3D Imaging

VCSEL laser arrays are now central to many sensing and imaging platforms:

Automotive LiDAR and ADAS – Long-range depth sensing, object detection and road profiling

3D facial recognition and access control – Secure, high-resolution depth maps for identity verification

Industrial 3D metrology – Structured-light projection and ToF sensing for inline quality control

In LiDAR and 3D sensing, arrays provide:

Dense dot patterns or tailored illumination geometries

Fast modulation for ToF measurements

Stable IR wavelengths that simplify optical filter design

Ace Photonics designs GaAs-based VCSEL arrays and modules that can be customized for structured light, ToF and active stereo systems, including non-magnetic, high-temperature packaging for harsh environments.

3. Consumer Electronics & Biometrics

Infrared VCSEL laser arrays enable many everyday user experiences:

Face unlock in smartphones and tablets

Gesture recognition in AR/VR headsets

Proximity and presence sensing in wearables and smart home devices

Compared with LEDs, VCSEL arrays offer:

Narrower wavelength spread for more robust algorithms

Higher modulation speeds for secure, anti-spoofing protocols

Uniform illumination across the field of view

Ace Photonics supports compact, low-power VCSEL solutions that integrate easily into mobile, wearable and IoT form factors.

4. Medical and Quantum Technologies

Ace Photonics also supplies VCSEL chips and arrays for specialized markets:

Medical diagnostics and imaging – Stable wavelengths for spectroscopy, pulse oximetry and imaging

Wearable health monitoring – Low-power light sources for continuous SpO₂, glucose and blood pressure tracking

Quantum sensing and atomic devices – Narrow linewidths and specific wavelengths (e.g., 795 nm / 895 nm) used in chip-scale atomic sensors and magnetometers

Custom array layouts, wavelength selection and packaging help device makers meet strict performance and regulatory requirements in healthcare and quantum applications.

Advantages of VCSEL Laser Arrays

From a manufacturer’s perspective, VCSEL laser arrays offer a balanced combination of performance, cost and manufacturability:

High-speed modulation – Supports multi-Gb/s links and fast ToF ranging

Superior beam control – Well-defined beam profiles and pattern shaping for structured light

Energy efficiency – High wall-plug efficiency reduces power and cooling needs

Compact, scalable design – Thousands of emitters on a single chip for high optical density

Wafer-level manufacturing – Facilitates testing, binning and cost-competitive volume production

Temperature and wavelength stability – Often eliminating the need for bulky active temperature control in many systems

Ace Photonics further enhances these advantages with non-magnetic, high-temperature packages and custom epitaxial structures tuned to each application.

Design Challenges and Considerations

Despite their strengths, several design aspects must be managed carefully when integrating VCSEL laser arrays:

Thermal management – Dense emitter layouts can generate significant heat. Substrate choice, heat-spreading design and package materials are critical to maintain junction temperatures and lifetime.

Eye safety and compliance – Especially in consumer and automotive LiDAR applications, system designers must shape and limit optical output to meet laser safety standards.

Optical design – Matching array geometry with microlens arrays, diffusers and system optics determines final beam uniformity and coverage.

Cost vs. performance trade-offs – Higher power or more complex packaging can increase cost; careful optimization is required for high-volume products.

Ace Photonics addresses these challenges through process control, in-line testing and robust packaging strategies designed for industrial-scale deployment.

Market Trends for VCSEL Laser Arrays

The global VCSEL market continues to grow, driven by:

Rising bandwidth demands in data centers

Expansion of LiDAR and 3D sensing in automotive and industry

Increasing use of biometrics and 3D cameras in consumer devices

Adoption of optical and quantum sensing in healthcare and research

Within this market, high-power VCSEL arrays at wavelengths around 795 nm, 895 nm and related bands are gaining attention for industrial, medical and quantum applications.

Manufacturers like Ace Photonics respond by:

Scaling production to reduce cost per watt

Offering more flexible array geometries and custom packaging

Providing engineering support from early design to mass production

Why Choose Ace Photonics for VCSEL Laser Arrays?

Ace Photonics is a dedicated VCSEL manufacturer focused on high-performance, application-specific solutions:

Full product portfolio – VCSEL die, VCSEL packages, VCSEL modules and gain chips to support different integration strategies.

Custom design from wafer to package – Tailored wavelengths, output power, array patterns and packaging for optical communication, LiDAR, 3D sensing, medical and quantum systems.

High-temperature and non-magnetic solutions – Suitable for harsh or magnetically sensitive environments, including aerospace and industrial automation.

Experienced R&D team – A background rooted in the Chinese Academy of Sciences, with long-term expertise in GaAs-based VCSEL processing, ICP etching, wet oxidation and advanced packaging.

From prototype support to volume manufacturing, Ace Photonics works closely with customers to translate system-level requirements into reliable VCSEL laser array solutions that are ready for integration.

Get Started with Custom VCSEL Laser Arrays

Whether you are developing a new LiDAR platform, upgrading data center links or designing a compact sensing module, a well-engineered VCSEL laser array can significantly improve performance and manufacturability.

Contact Ace Photonics to discuss:

Target wavelength and power levels

Required array geometry and beam pattern

Packaging, operating temperature and environmental constraints

Compliance and testing needs for your industry

Our engineering team can help you move from concept to stable, production-ready VCSEL laser array solutions tailored to your application.