Ace Photonics: Specialist VCSEL Laser Diode Manufacturers

In markets where every photon matters—quantum sensing, 3D imaging, precision instrumentation—choosing the right VCSEL laser diode manufacturers is critical. Ace Photonics focuses exclusively on VCSEL technology, delivering laser dies, gain chips, packages and modules that bridge the gap between research-grade performance and robust industrial deployment.

What Is a VCSEL Laser Diode?

A VCSEL (Vertical-Cavity Surface-Emitting Laser) is a semiconductor laser diode that emits light vertically from the surface of the chip instead of from the cleaved edge. This vertical emission geometry allows full wafer-level testing, compact arrays and cost-effective high-volume production.

Compared with traditional edge-emitting lasers, VCSEL laser diodes combine:

Laser-class coherence and narrow linewidth

LED-like manufacturing scalability and cost advantages

Symmetric, low-divergence output that is easy to collimate or couple into multimode fiber

These properties make VCSELs the light source of choice in data communications, sensing, imaging, consumer electronics and next-generation quantum devices.

Why System Designers Choose VCSEL Technology

From a system architect’s perspective, VCSELs bring several practical advantages:

High wall-plug efficiency & low threshold current – ideal for battery-powered devices, UAVs, IoT nodes and thermally constrained designs.

Wafer-surface emission – enables complete wafer-level probing before dicing, improving yield and traceability.

Scalable arrays – easy to integrate into high-power VCSEL arrays and multi-channel modules.

Excellent wavelength stability over temperature – supports narrowband filtering and precise spectroscopy.

Ace Photonics designs VCSELs specifically to exploit these strengths in demanding commercial and scientific environments.

Ace Photonics as VCSEL Laser Diode Manufacturers

Deep Expertise in GaAs-Based VCSELs

Ace Photonics is built around GaAs-based VCSEL research and production. The team has long-term experience in semiconductor laser design, epitaxial growth and chip processing, serving both industrial customers and R&D labs worldwide.

Key process capabilities include:

Custom epitaxial stack design for specific wavelengths and thermal budgets

Advanced chip processing such as ICP etching, wet oxidation and BCB planarization

Device engineering for high-temperature operation and long-term reliability

This combination lets Ace Photonics act not just as a component supplier, but as an engineering partner for application-driven VCSEL design.

Product Portfolio: From Bare Dies to Complete VCSEL Modules

Ace Photonics offers a vertically integrated VCSEL portfolio tailored to different integration levels and markets.

VCSEL Die

Single-mode VCSEL dies covering roughly the 750–900 nm band for sensing and spectroscopy

Optimized lines at 795 nm and 895 nm for atomic and quantum sensing platforms

High-power options where output in the lab already approaches several milliwatts in single-mode operation

The surface-emitting die architecture supports wafer-level testing, fine binning and custom die layouts for arrays or chip-scale packaging.

VCSEL Gain Chips

For customers building their own optical benches or integrating custom resonators, VCSEL gain chips provide:

High-power active regions for modules that require external optics

Compatibility with frequency-conversion optics and specialized lens stacks used in laser processing and medical tools

VCSEL Packages

Ace Photonics supplies a range of standard and application-specific packages, including:

SMD VCSEL packages for compact consumer and industrial electronics

TO-46 VCSEL cans for lab setups and robust OEM modules

Non-magnetic VCSEL packages using ceramics or specialty composites for sensitive quantum magnetometers and other precision sensors

Many packages combine the VCSEL chip with integrated thermistors or TECs to stabilize wavelength and output power over wide temperature ranges.

VCSEL Modules

For plug-and-play integration, Ace Photonics VCSEL modules combine:

VCSEL gain chip

Collimating and focusing optics

Optional frequency-conversion elements

Electrical interface tailored to the target system

These modules are used in laser processing, demonstration systems, laser medicine and other application-specific platforms.

Application Focus: Where Ace Photonics VCSELs Excel

Quantum Sensing & Precision Instrumentation

Ace Photonics single-mode VCSELs at 795 nm and 895 nm are engineered for atomic spectroscopy and quantum sensing, including NV centers in diamond, alkali-vapor cells and cold-atom setups.

Non-magnetic VCSEL packages reduce parasitic magnetic fields in shielded enclosures, helping quantum magnetometers and other sensors reach femtotesla-level sensitivities.

3D Sensing, Imaging and Consumer Electronics

VCSEL arrays are now a workhorse light source for:

Facial recognition and biometric authentication

Structured-light and ToF depth cameras

AR/VR and smart-glasses illumination

High efficiency, low speckle and controllable beam shaping through micro-optics make Ace Photonics VCSELs well suited to compact consumer modules.

Data Communications & Telecom

In short-reach multimode fiber links, VCSELs offer high-speed, low-loss transmission with attractive cost per channel. Ace Photonics provides devices optimized for:

Rack-to-rack and in-rack links in data centers

Active optical cables and high-density interconnects

Short-range industrial and automotive networking

Industrial, Medical and Emerging Markets

With high-power VCSEL dies and modules, Ace Photonics supports:

Laser processing and materials modification

Laser demonstration and education platforms

Medical imaging and non-invasive sensing

Agricultural and environmental monitoring systems using low-power, efficient VCSEL illumination

Manufacturing Excellence and Quality Assurance

Ace Photonics combines wafer-level fabrication with stringent testing to ensure consistent performance from prototype through volume production.

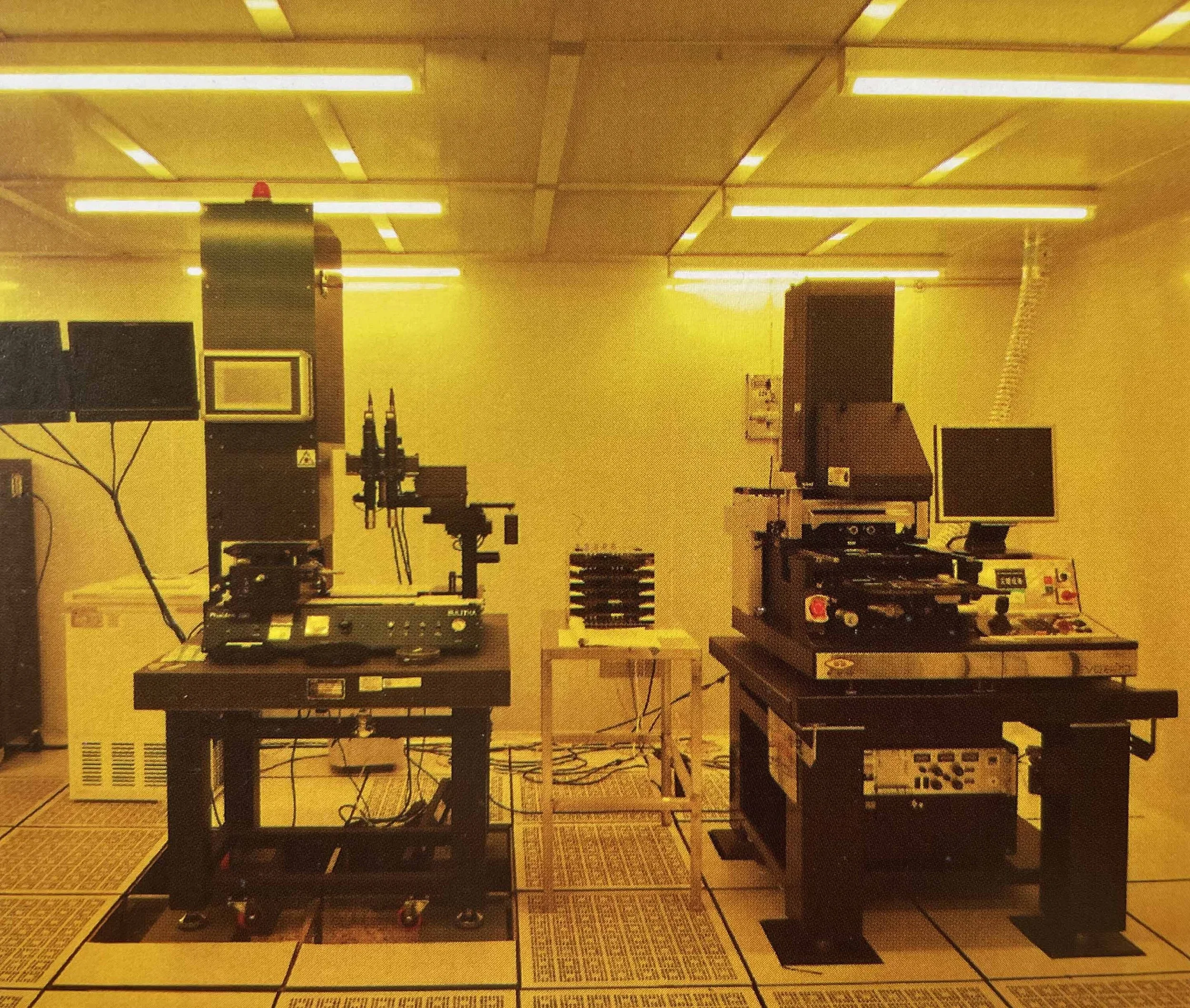

State-of-the-Art Facilities

Wafer-level VCSEL processing with advanced etching, oxidation and passivation steps

High-temperature design and qualification—many VCSEL products are rated for operation up to 150 °C, supporting harsh environments.

Aerospace-inspired development and test workflows for special-environment applications

Rigorous Testing & Reliability

Each VCSEL die, package or module undergoes:

Electrical and optical characterization at multiple drive currents and temperatures

Beam-profile and divergence checks

Wavelength and polarization stability verification for sensing applications

This approach gives OEMs repeatable performance and predictable lifetime in the field.

Custom Design: Beyond Standard VCSEL Laser Diodes

As VCSEL laser diode manufacturers, Ace Photonics recognizes that off-the-shelf parts rarely fit every specification. The company offers end-to-end customization, including:

Tailored epitaxial structures for specific wavelengths, output powers and thermal constraints

Custom aperture sizes and array layouts for structured-light or high-power applications

Packaging optimized for footprint, magnetic cleanliness, thermal path and integration method

Application-driven module design, including lens stacks and frequency-conversion optics

Engineering teams work directly with customers’ optical, mechanical and systems engineers, shortening design cycles and de-risking new platforms.

Environmental and Sustainability Considerations

Ace Photonics’ focus on efficient VCSELs inherently supports lower power consumption at the system level—fewer watts dissipated in data centers, edge devices and instrumentation.

Combined with long device lifetimes and robust packaging, this reduces maintenance, electronic waste and overall lifecycle impact.

Why Choose Ace Photonics Among VCSEL Laser Diode Manufacturers?

When benchmarked against generic VCSEL suppliers, Ace Photonics stands out for:

Narrow specialization in VCSEL technology – deep GaAs and quantum-source expertise

Complete portfolio – die, gain chips, packages and modules from one supplier

Custom non-magnetic and high-temperature solutions for cutting-edge sensing

Strong ties to research and industry – experience with labs, universities and OEMs worldwide

Engineering-driven collaboration – from concept to qualification, not just catalog parts

For system designers building the next generation of quantum sensors, depth cameras, advanced medical instruments or high-speed links, partnering with Ace Photonics means working with a VCSEL manufacturer that understands both device physics and real-world integration.